Page 6

SKU 9

9856

-96154

for technical questions, please call 1-800-444-3353.

Part

description

Q’ty

Part

description

Q’ty

1

Relay, Start-Up

1

13

Cable, Starter Motor

1

Rotor Comp.

1

14

Insulator

1

3

Starting Clutch

1

15

Bolt (M5x14)

4

Starter Motor Assy.

1

16

Screw (M4x6)

1

5

Base, Starter

1

17

Packing Ring

1

6

Housing, Starter Clutch

1

18

Screw (M5x32)

4

7

Drive Gear

1

19

Nut (M6)

8

Brush, Comp.

4

20

Bolt (M6x35)

9

Stator Assy.

1

1

Spring Washer (4mm)

3

10

Spring, Brush

4

Screw (M4x14)

11

Reducing Gear

1

3

Washer (4mm)

1

Stay, Brush

1

4

Set Pin (8x14)

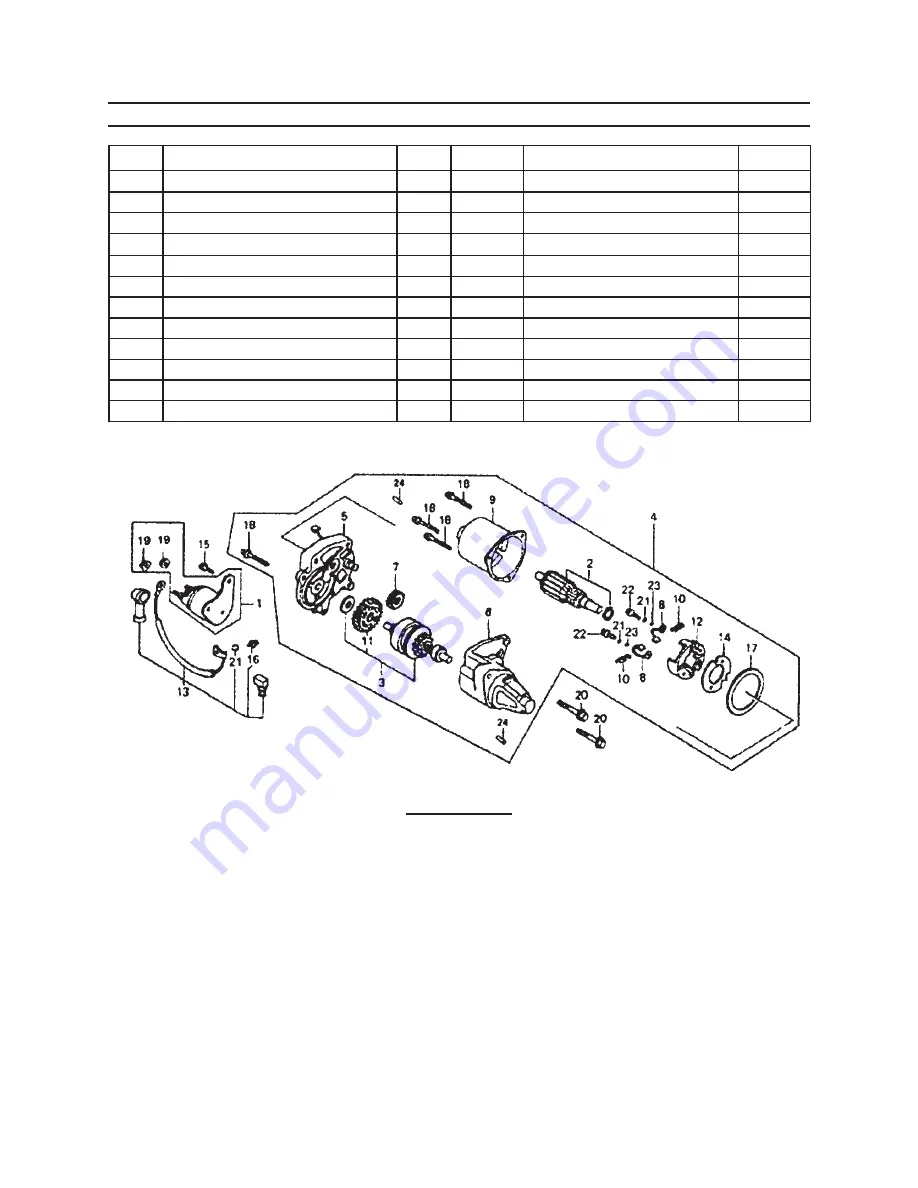

PARTS LIST/dIAGRAM - STARTER MOTOR

IMPORTANT

When ordering parts from the above Parts List, make sure to specify the following:

The MOdEL NuMbER (either 9

9856

or 96154) of the Engine for which you are ordering.

The PART NuMbER listed to the left of the part description.

The NAME Of THE PARTS LIST from which you are ordering (located at the top of this page).

a.

b.

c.