Page 8

For technical questions, please call 1-800-444-3353.

SKU 44505

sPeciFicatiOns

Electrical Input 120 V~, 60 Hz, 1/3 HP (3.6 A)

Motor Speed

1750 RPM (No Load)

Spindle Speeds 620, 1100, 1720, 2340, and 3100 RPM

Spindle Stroke

2”

Base

11-1/8” x 6-3/8”; Slot: 9/16”

Throat Depth

4” (of 8” swing)

Chuck

1/2”, keyless

Table Rotation

360°; Tilt: 45° (left and right)

Table Size

6-5/8” x 6-3/8”

Table Slot

5/8”

e105017

unPacking

When unpacking, make sure that the

item is intact and undamaged. If any parts

are missing or broken, please call Harbor

Freight Tools at 1-800-444-3353 as soon as

possible.

Assembly hardware is located in

separate bags/boxes. Each contains the

necessary parts for each assembly step.

Remove all packing and protective material

from the Drill Press components.

instructiOns FOr Putting

intO use

read the entire iMPOrtant

saFetY inFOrMatiOn

section at the beginning of this

manual including all text under

subheadings therein before set up

or use of this product.

tO PreVent

seriOus injurY

FrOM acciDental

OPeratiOn:

turn the Power switch of the tool

to its “OFF” position and unplug

the tool from its electrical outlet

before assembling or making any

adjustments to the tool.

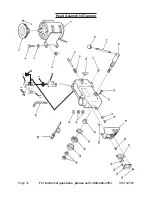

note:

For additional information regarding the

parts listed in the following pages, refer

to the Assembly Diagram near the end of

this manual.

assembly/Mounting

note:

Assembly hardware is located in

separate bags/boxes.

Position the

1.

base

(C4) on a level and

sturdy table for mounting.

It is recommended to bolt the Base to the

table using appropriate hardware (not

supplied).

Place the

2.

support tube

(C3) on the

Base, aligning the mounting holes.

Insert three large Hex Screws (C5) into

3.

the mounting holes and tighten.

Install the

4.

table support

(C1), with

attached Table (C7), over the Support

Tube (C3) and slide it down. Hand

tighten the Lock Handle Support (C2).

cautiOn! avoid injuries. the next step

involves lifting the head assembly

onto the support tube. the head

assembly is heavy. have someone

help you lift this assembly into place.

set

screws

(11)

Feed

knob (12)

guard (a5)

knob

(a2)

Motor

adjusting

knob (10)

5.

Using two people, lift the

head (1)

assembly

up and onto the Support Tube

(C3).

Slide it down on the Column Tube as

far as it will go. Align it so that it faces

straight forward, inline with the Base.