Page 5

SKU 90288

For technical questions, please call 1-800-444-3353.

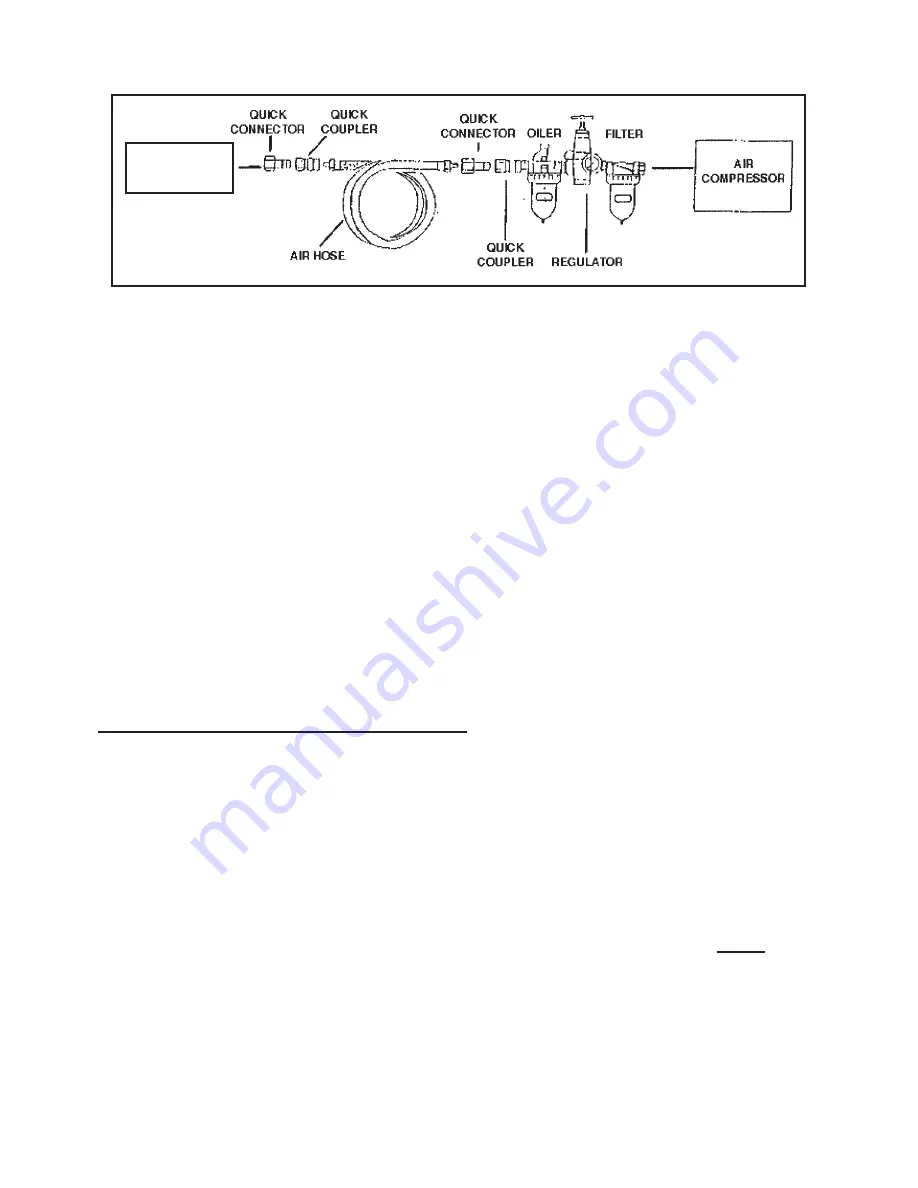

Air Connection

AIR SANDER

Note: Air Compressor is not supplied. You will need an Air Compressor with a

minimum rating of one horsepower, 4 CFM delivery at 90 PSI, and a 12 Gallon Air

Tank. Refer to the above illustration for complete air connection setup.

You may use Quick Connectors, Quick Couplers, (not supplied) and Air Regulator

as shown in the Diagram above. Do not connect Couplers directly to the Air Inlet

(2). Doing so will increase the overall bulk of the tool and strain the Inlet Threads.

Be sure to follow all safety precautions as listed on Pages 2-4 of this manual and

the instruction manual for the Air Compressor being used.

This air tool requires lubrication during operation. For best results, it is recom-

mended to have an oiler and water filter in line with the air supply as shown in the

diagram above. This will extend the life of the tool.

To Attach Sanding Paper And The Pad:

1.

Ensure that the Pad is

firmly

screwed onto the Drive Spindle (38). The

Spindle Lock (41) turns to engage the Drive Spindle (38), allowing the

Pad (44) to be threaded on securely. Turn the Spindle Lock (41) back out

of the way before use.

If the Orbital Hub is still in the locked position

during use, then the Sander will not operate properly. (See Bottom

View, next page.)

2.

The Sander

only

uses

6” diameter, PSA Stick,

(self-sticking) Sanding

Paper (not included). Make sure to attach the Sanding Paper firmly to

the Pad (44).

REV 05e