Page 7

SKU 90288

For technical questions, please call 1-800-444-3353.

distance from the sanding pad while the Sander is operating. Do not force the

Pad or apply too much pressure. If the Pad slows down as you work with your

material, you are applying too much pressure. Always keep your body and

clothing a safe distance from the running Air Sander.

8. Once you have turned the Sander off, continue to hold onto the tool with both

hands until the Pad stops spinning completely and before you set it down.

Disconnect Sander from compressor when finished.

NOTE:

Some parts are listed and shown for illustration purposes only and are not avail-

able individually as replacement parts.

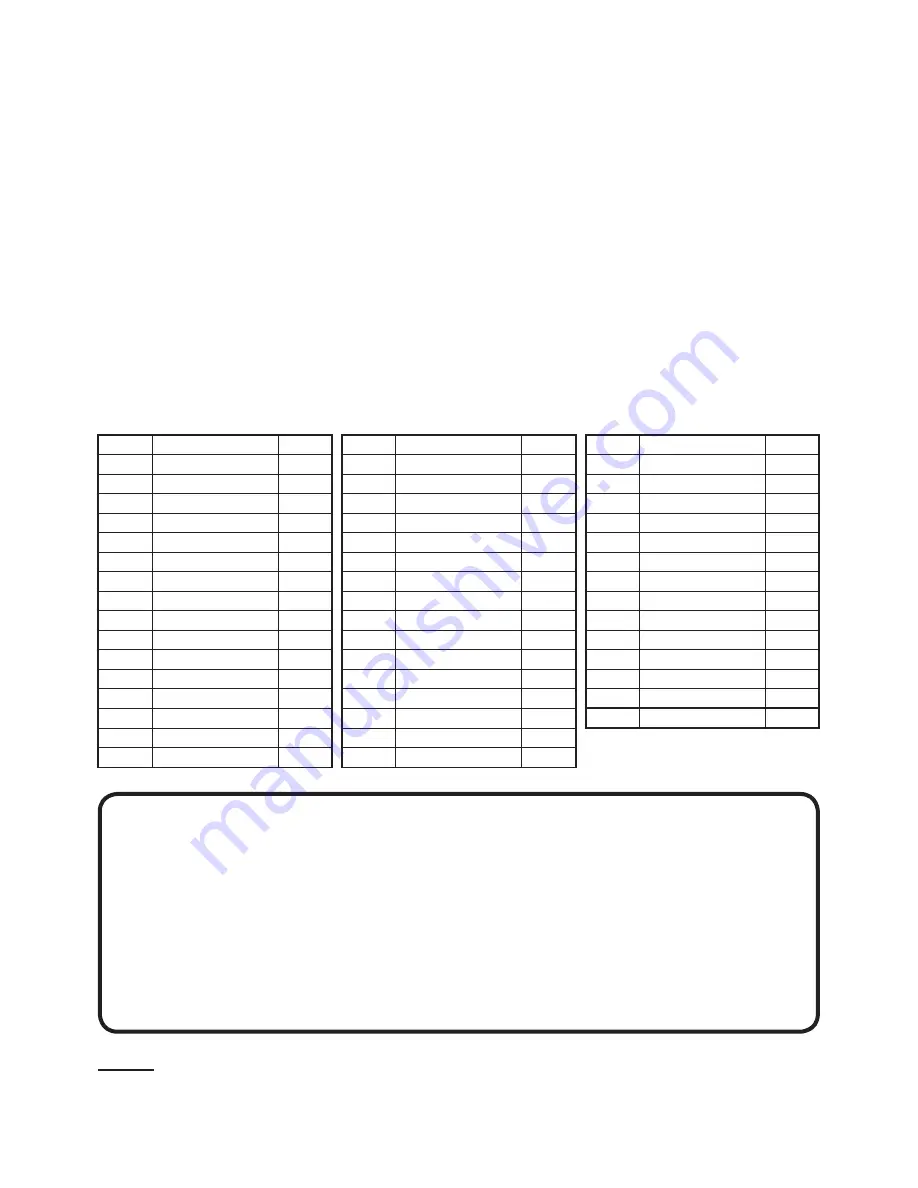

Parts List

Part

Description

Q’ty

1

Housing

1

2

Air Inlet

1

3

O-Ring

1

4

Spring

1

5

O-Ring

4

6

Valve Stem

1

7

O-Ring

1

8

O-Ring

1

9

O-Ring

1

10

Valve Body

1

11

Screw

1

12

Bracket

1

13

Trigger Screw

1

14

Screw

1

15

Cap

1

16

Trigger

1

Part

Description

Q’ty

17

Rubber

1

18

Retainer Ring

1

19

Air Regulator

1

20

Retainer Ring

1

21

Bearing

2

22

End Plate

2

23

Cylinder

1

24

O-Ring

1

25

Pin

1

26

Rotor

1

27

Rotor Blade

5

28

Work Spindle

1

29

Woodruff Key

1

30

Rear Gasket

1

31

Rear Cover

1

32

Screw

2

Part

Description

Q’ty

33

Screw

2

34

Balancer

1

35

Screw

1

36

Screw

1

37

Bearing

1

38

Drive Spindle

1

39

Retainer Ring

1

40

Cap

1

41

Spindle Lock

1

42

Washer

1

43

Screw

1

44

Pad

1

45

Washer

1

46

Wrench

1

PLEASE READ ThE FOLLOWINg CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM

IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DIS-

TRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT

HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE

IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER

AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS

SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND NOT BY THE

BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS

TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS

OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

REV 04i, 04k, 05e, 06d, 10f

Maintenance

Be sure to follow all recommended steps for Maintenance as listed on Pages 3-4.

Sanding Pads must be clean and sharp for maximum sanding efficiency and

safety. Do not use cracked or torn Sanding Pads.