Page 6

SKU 40115

Note: Have the following problems repaired by an authorized service technician.

1. Problem: Air leaking at trigger valve area.

Probable Cause: Damaged 0-rings in trigger valve housing.

Solution: Replace 0-rings. Then re-check contact safety trip mechanism.

2. Problem: Air leaking between housing and nose.

Probable Cause: Loose screws in housing, damaged 0-rings or bumper.

Solution: Tighten screws or replace 0-rings or bumper.

3. Problem: Air leaking between housing and End Cap.

Probable Cause: Loose screws or damaged gasket.

Solution: Tighten Screws or replace gasket.

4. Problem: Runs slowly or has power loss.

Probable Cause: Nailer/Stapler insufficiently oiled, broken spring in cylinder cap, exhaust

port in cap is blocked.

Solution: Lubricate as instructed, install new spring, Replace damaged internal parts.

5. Problem: Nailer/Stapler skips driving nail or staple.

Probable Cause: Worn or dirty bumper, damaged pusher spring, inadequate air flow, worn

or dry 0-ring on piston, damaged 0-ring on trigger valve, cap gasket leaking.

Solution: Replace bumper or pusher spring, clean bumper and drive channel, check fittings,

replace or lubricate 0-rings, replace gasket.

6. Problem: Nails or staples are jammed in Nailer/Stapler or nose.

Probable Cause: Guide on driver is worn. Wrong size or damaged nails or staples, loose

magazine or nose screws, damaged driver.

Solution: Replace guide, use recommended / undamaged nails or staples, tighten screws,

replace driver.

7. Problem: Nailer/Stapler will not drive down tight.

Probable Cause: Rounded driver blade causing slippage, power loss, slow cycling and

power loss.

Solution: Replace blade, adjust air pressure, check spring under cap for broken coils or

reduce length, check if cap in exhaust port is restricted.

8. Problem: Blade driving nail or staple too deeply.

Probable Cause: Worn bumper or piston spacer.

Solution: Replace either or both parts.

Maintenance

Warning! Always disconnect the tool from the air compressor and then empty the magazine

of nails or staples before attempting to inspect or perform maintenance to the Nailer/Stapler.

1. Inspect all of the nuts and screws and make sure they are securely fastened.

2. Periodically lubricate the driving mechanism and magazine with a light oil. Wipe down with

a clean cloth. Never use gasoline or flammable solvents to clean the tool.

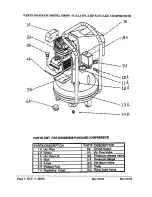

3. Inspect your air compressor according to manufacturer’s instructions.

Warning! If you detect any air leaks, power loss, the Nailer/Stapler skips driving, drives too

deep, or not deep enough, take the Nailer/Stapler to a qualified service technician.

Warning! If you detect any air leaks, power loss, the Nailer/Stapler skips driving, drives too

deep, or not deep enough, take the Nailer/Stapler to an authorized service technician for

repair.

Troubleshooting