Page 7

SKU 41209

For technical questions, please call 1-800-444-3353.

5.

Connect the air supply to the tool at the Air Plug (17). Set the regulator at the

recommended

65 PSI

to

100 PSI

.

Do not to go over the maximum 100 PSI.

6.

Test the tool by depressing the nose against the workpiece without pulling the

Trigger (42).

The Tool must not cycle (fire).

If it cycles (fires), stop immedi-

ately and have it repaired by a qualified service technician.

7.

Hold the tool away or off of the workpiece. The Nose (72) of the tool should

return to its original position. Squeeze the Trigger (42).

The tool should not

cycle (fire).

If the tool fires, stop immediately and have it repaired by a qualified

service technician.

8.

Depress the Nose (72) against the workpiece and squeeze the Trigger (42).

The

tool must cycle (fire).

Release the Trigger and squeeze it again.

The tool must

cycle (fire).

With the Trigger held, carefully lift the Nailer and press it against the

workpiece again.

The tool must cycle (fire).

If it fails to perform in the manner

explained in bold, have it repaired by a qualified service technician.

Loading Coil Nails

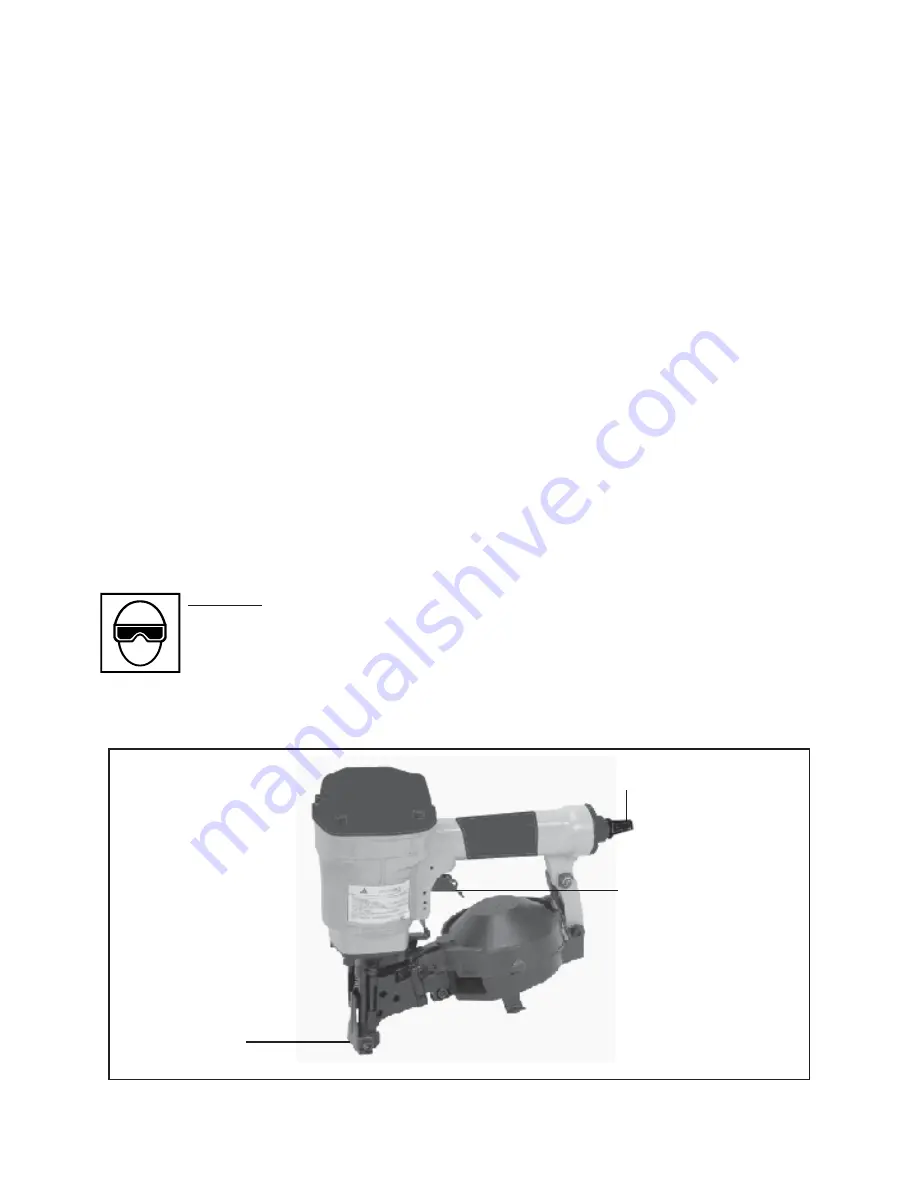

ALWAYS WEAR ANSI APPROVED IMPACT SAFETY GOGGLES WHEN

RELOADING OR DOING ANY OTHER MAINTENANCE ON THIS TOOL.

Other people in the work area must also wear ANSI approved impact safety

goggles.

Warning! Make sure the Nailer is not attached to the air hose whenever loading

the tool.

NOSE (72)

TRIGGER (42)

AIR PLUG (17)