Page 12

For technical questions, please call 1-888-866-5797.

Item 42202

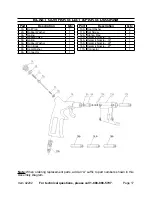

can easily move your hands and grip

objects.

4.

Grip the gun with one hand. Point the

nozzle at the bottom of the Cabinet

and operate the Gun for a moment

to ensure everything is working

correctly. If leaking is detected, or

blasting material dust is escaping

the side door seals, disconnect the

air hose and have it repaired before

using.

5.

Hold the object you are working with

in your other hand. Position your

fingers so the Blast Glove (18) is

not in the way of the area you are

blasting. You may have to re-position

your fingers many times during the

blasting to ensure that you reach

every area of your object.

6.

Squeeze the Trigger on the Blast

Gun to begin operation. Release the

Trigger to stop.

Aim the nozzle directly at the surface

of the material. Bring the nozzle

to within 2 inches of the material if

necessary. Move the Gun in a side-

to-side or circular motion, always

making sure that your fingers are not

in the way.

Use even passes of the Gun to

remove rust, body filler, or other soft

materials.

7.

To check on the progress of your

blasting, remove your hand from

the gun first and pull your hand

from the Glove. Remove your other

hand. Once the gun is off, open the

door and inspect your material. If

additional blasting is required, follow

steps 1 through 7 as needed.

Note:

Use caution when sandblasting

unfamiliar material. Test the tool on

a small area before proceeding. This

will ensure you will not damage or pit

the material you wish to sandblast.

WARNING:

Do not aim the gun at your

fingers or the Blast Gloves. Do not

operate the gun with the Side Door

open or outside of the Blast Cabinet.

8.

If the tool requires more force to

accomplish the task, verify that the

tool receives sufficient, unobstructed

airflow (CFM) and increase the

pressure (PSI) output of the regulator

up to the maximum air pressure

rating of this tool.

CAUTION! TO PREVENT TOOL

AND ACCESSORY FAILURE,

RESULTING IN INJURY:

Do not exceed the tool’s maximum

air pressure rating.

If the tool still does not have sufficient

force at maximum pressure and

sufficient airflow, then a larger tool

may be required.

9.

Once completed, remove your hands

from the Gloves and shut off the

compressor. Open the Side Door and

remove your material from the Blast

Cabinet.

10. To prevent accidents, turn off the

tool, detach the air supply, safely

discharge any residual air pressure in

the tool, and release the Trigger after

use. Clean external surfaces of the

tool with a clean, dry cloth, and apply

a thin coat of tool oil. Then store the

tool indoors out of children’s reach.