Page 13

For technical questions, please call 1-888-866-5797.

Item 42202

USER-MAINTENANCE

INSTRUCTIONS

Procedures not specifically

explained in this manual

must be performed only by a

qualified technician.

TO PREVENT

SERIOUS INJURY

FROM ACCIDENTAL

OPERATION:

Release the Trigger, detach

the air supply, safely

discharge any residual air

pressure in the tool, and

release the Trigger again

before performing any

inspection, maintenance, or

cleaning procedures.

TO PREVENT SERIOUS

INJURY FROM TOOL

FAILURE:

Do not use damaged

equipment. If abnormal

noise, vibration, or leaking

air occurs, have the problem

corrected before further use.

Cleaning and Maintenance

Note:

These procedures are in addition to

the regular checks and maintenance

explained as part of the regular

operation of the air-operated tool.

Changing the Blasting Medium

It is not necessary to remove the

blasting medium from the Hopper

(13) after every use. However, clean

out the Hopper when a different

blasting medium is to be used or

when the medium gets worn down.

To clean the Hopper:

WARNING:

Wear ANSI-approved safety

goggles, full face shield and a

NIOSH-approved protective dust

mask or respirator when replacing

the abrasive medium in the Blast

Cabinet.

1.

Disconnect the dust collection system

from the Blast Cabinet.

2.

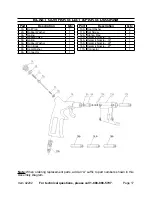

Disconnect Air Hose and Syphon

Hoses from the Gun.

3.

Remove the Gun from the Cabinet.

4.

Pull the Gloves through the glove

holes so that they are out of the way

of the inside of the Blast Cabinet.

5.

Remove the Metal Floor from the

Blast Cabinet.

6.

Straddle the Blast Cabinet over two

saw horses (sold separately) with an

open container below which is large

enough to hold the abrasive material

in the hopper.

7.

Unthread the Cap (9) at the bottom

of the Hopper and allow the abrasive

medium to flow into the container.

8.

Use your compressor set at 10 PSI

to help blow any excess abrasive out

of the hopper and into the container.

Also, use the compressor to clean

abrasive out of the Blast Gun and the

Siphon Hose (8) and Siphon Tube

(12).

9.

Replace the Cap and the Metal Floor

once the Hopper is empty.

10. Push the Gloves back into the Blast

Cabinet.

11. Reassemble the Siphon Hose,

Siphon Tube and Blast Gun and