Page 8

For technical questions, please call 1-888-866-5797.

Item 42202

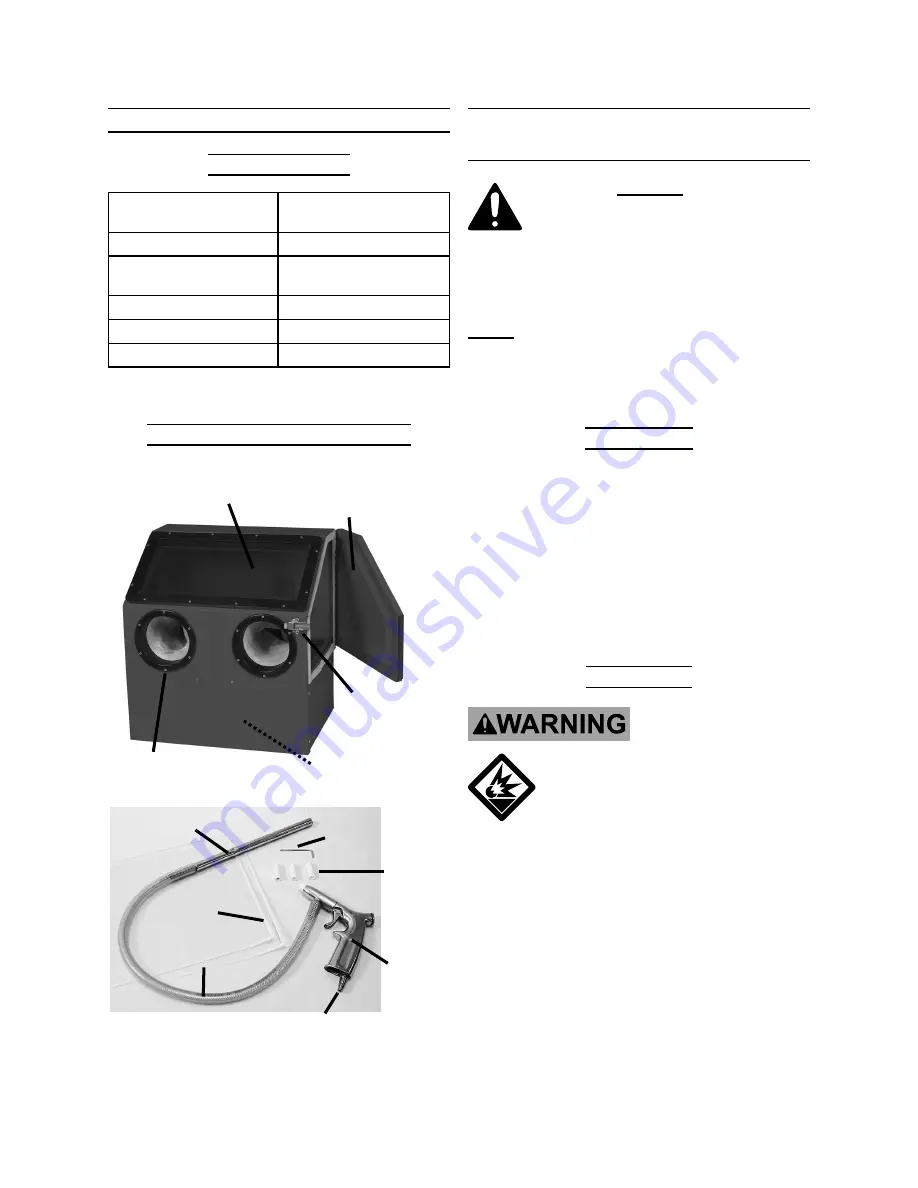

FUNCTIONAL DESCRIPTION

Specifications

Compressor

Requirements

1 HP or larger

compressor

Air Inlet

1/4″ NPT

Nozzle Type

Ceramic - .18″, .19″,

.22″, .27″

Air Consumption

10 CFM @ 100 PSI

Operating Air Pressure

Up to 100 PSI

Hopper Capacity

30 lb

Use of 3/8″ supply hose is recommended.

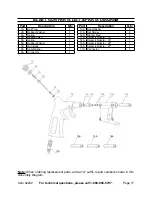

Components and Controls

Hopper (13)

Glove Port (16)

Tempered

Glass Window

(23)

Side Door (3)

Door

Latch

(5)

Blast Gun (7)

Siphon Hose (8)

Siphon Tube (12)

Ceramic

Nozzles

(13A - 16A)

Air Hose Connector (30)

Window Liners (22)

Hex

Wrench

Figure 1

INITIAL TOOL SET UP/

ASSEMBLY

Read the ENTIRE IMPORTANT

SAFETY INFORMATION

section at the beginning of this

manual including all text under

subheadings therein before set

up or use of this product.

Note:

For additional information regarding

the parts listed in the following pages,

refer to the Assembly Diagram near

the end of this manual.

Unpacking

When unpacking, make sure that

the is intact and undamaged. If any

parts are missing or broken, please call

Harbor Freight Tools at 1-888-866-5797 as

soon as possible.

• This air tool may be shipped with a

protective plug covering the air inlet.

Remove this plug before set up.

Air Supply

TO PREVENT

EXPLOSION:

Use only clean, dry, regulated,

compressed air to power this

tool. Do not use oxygen,

carbon dioxide, combustible

gases, or any other bottled

gas as a power source for this

tool.