Page 6

SKU 45214

Operation (continued)

Operational Warnings:

1. To reduce the risk of explosion or fire, never spray flammable liquids in a confined area.

Make sure the work area is well ventilated. Never smoke while spraying. Never spray near

flames or sparks. Keep compressor away from all flammable objects.

2. Air from a compressor is not suitable for breathing purposes. Never inhale air from the

compressor.

3. Never alter or weld on the air compressor tank. Welding on a tank is extremely hazardous

and could affect tank strength; this may result in an explosion, causing severe injury or death.

4. Never use the compressor outdoors in the rain, or on a wet surface. Electric shock may

result.

5. Never make adjustments or work on the compressor when it is pressurized.

6. Never service or perform maintenance on the air compressor until it is depressurized and

unplugged.

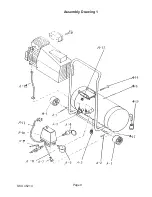

7. When not in use, always put the Air Pressure Switch (A-10) in the off, or down position.

Maintenance

Warning! Make sure the compressor tank is drained and the compressor is unplugged

before attempting any maintenance.

Never use flammable liquids or solvents to clean the compressor. Clean with a mild detergent

and water. Be careful to not spill water onto electrical components.

Each use.

1.

Check oil level. If needed, fill according to instructions on page 5.

2. Drain air tank. Turn the Water Valve (#A-5) clockwise. Reverse to close. It is good prac-

tice to leave it open between uses, to keep tank dry.

3. Check for worn or damaged cords or plugs.

After first 50 hours or 30 days.

1.

Replace the oil. See the top of page 5.

2. Check to make sure fittings are tight.

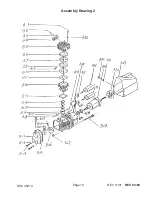

3. Blow air and clean out the cylinder cooling fins on Cylinder Head (#B-5).

Weekly.

1. Remove the Air Filter (#B-4), wash it with water, allow it to dry, then install it. To remove

filter, remove the Screw (#B-2) and Washer (#B-3). Reverse procedure to re-install.

REV 02/04