Page 9

For technical questions, please call 1-800-444-3353.

Item 56101

Operation

Read the ENTIRE IMPORTANT SAFETY INFORMATION section at the beginning of this manual

including all text under subheadings therein before set up or use of this product.

Using the Compressor

Inspect Compressor, engine, pump and equipment looking for damaged, loose, and missing parts

before set up and starting. If any problems are found, do not use equipment until fixed properly.

Note:

At the beginning of the day’s first use of the Air Compressor, check for air leaks by applying soapy water to

connections while the Air Compressor is pumping and after pressure cut-out. Look for air bubbles. If air bubbles

are present at connections, tighten connections. Do not use the air compressor unless all connections are air tight.

The extra air leaking out will cause the compressor to operate too often, increasing wear on the compressor.

Before starting the Compressor:

a.

Follow the Set Up Instructions in the equipment manual to prepare the equipment.

b.

Follow the Set Up Instructions in the Engine manual to prepare the engine.

c.

Inspect all components of the setup. Make sure all nuts and bolts are tight.

d.

Fill the Engine with the proper amount and type of both fuel and oil.

e.

Fill the Compressor Pump with compressor oil following the Maintenance Instructions in this manual.

To Start and Use the Compressor

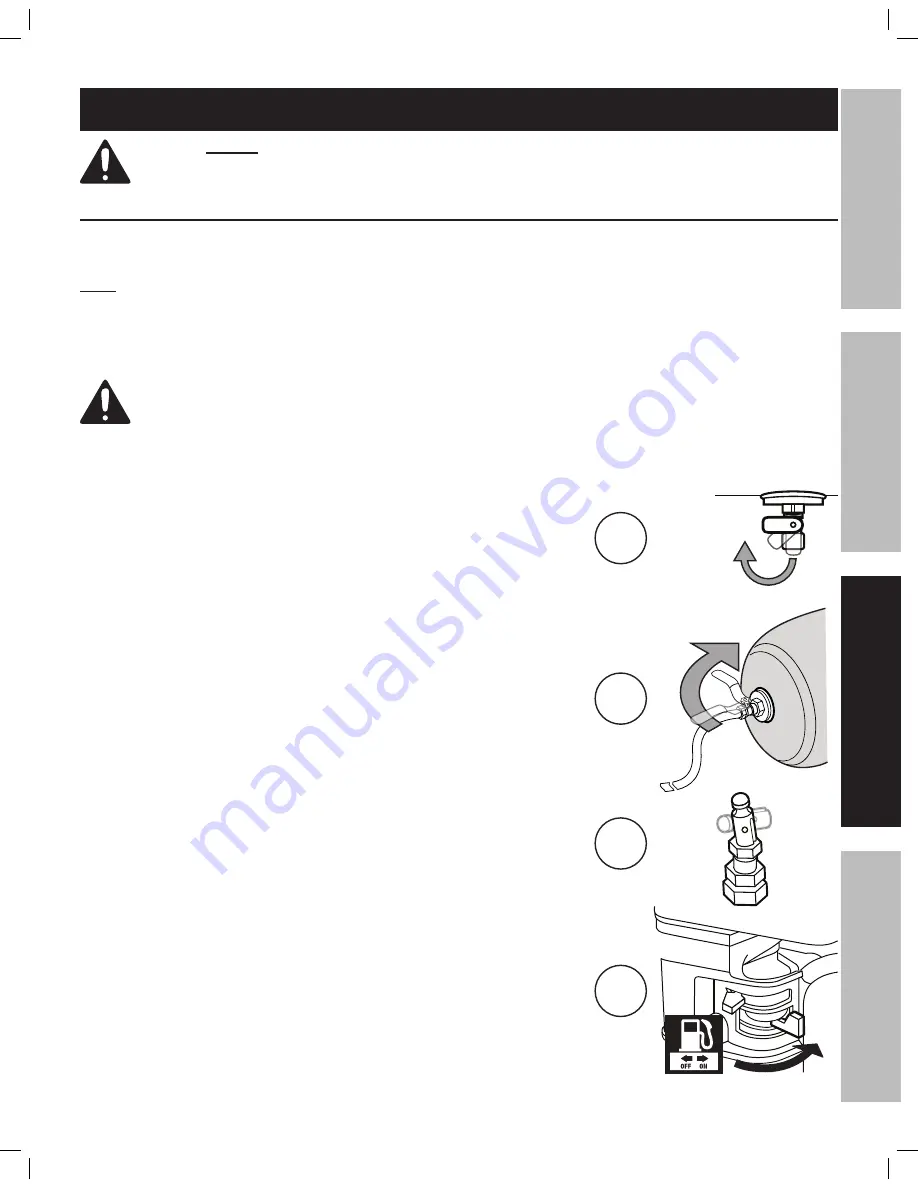

1. Close the Drain Valve (137) by turning the lever up so that it

is perpendicular to the valve.

2. Close the in-line Shutoff Valve between the compressor and

the air hose.

3. Open the Pilot Valve by rotating it to a vertical position.

4. Open the Fuel Valve.

3

4

1

2

SAFETY

OPERA

TION

MAINTENANCE

SETUP