Page 3

For technical questions, please call 1-800-444-3353.

Item 60754

SAFET

y

M

AINTENAN

c

E

PARTS LIST

SETUP

General Safety Warnings (continued)

3.

compressor Pump use and care

a.

Disconnect the plug of the compressor

motor from the power source before

installing, making any adjustments, changing

accessories, or storing the compressor

Pump.

Such preventive safety measures

reduce the risk of starting the unit accidentally.

b.

Store an idle compressor pump out of the

reach of children and do not allow persons

unfamiliar with the compressor pump or these

instructions to operate it.

A compressor pump

is dangerous in the hands of untrained users.

c.

Maintain the compressor Pump. Keep the

compressor Pump clean for better and

safer performance. Follow instructions

for lubricating and changing accessories.

Keep dry, clean and free from oil and grease.

check for misalignment or binding of moving

parts, breakage of parts and any other

condition that may affect the compressor’s

operation. If damaged, have the compressor

repaired before use.

Many accidents are caused

by a poorly maintained compressor pump.

d.

Use the compressor Pump in accordance

with these instructions, taking into account

the working conditions and the work to be

performed.

Use of the Compressor Pump

for operations different from those intended

could result in a hazardous situation.

4.

Service

a.

Have the compressor Pump serviced by a

qualified repair person using only identical

replacement parts.

This will ensure that the

safety of the Compressor Pump is maintained.

compressor Pump Safety Warnings

1.

ONLy a qualified engineer with appropriate

certifications may attempt designing a new

compressor to ensure that all required safety

and control elements are in place and will work

together properly and safely. This compressor

pump is intended ONLy as a replacement

for a similarly rated pump on an existing

compressor that includes all other needed

components. constructing a new compressor

using this pump is not covered by this manual.

2.

Use Safety Guard for Pulleys.

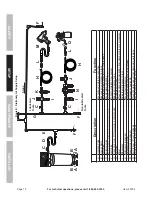

The Air

Compressor Pump Pulley (45), V-belts (not

included), and motor pulley (not included) must

be covered by a safety guard (not included)

covering all moving elements before operation.

3.

Before first and every use, verify

Pump has sufficient oil.

4. The use of accessories or attachments not

recommended by the manufacturer may

result in a risk of injury to persons.

5.

Misalignment between Motor and Pump

can damage the Pump Pulley.

Use a

straight edge, such as a yardstick, to check

and adjust alignment as needed.

6.

Use proper size motor and motor pulley.

This Air Compressor Pump must be installed

with a 5 HP electric motor and pulley (both not

included) which can turn the Air Compressor

Pump Pulley at approximately 1050 rpm.

7.

Install motor, pulley belts and pulley belt

cover securely.

Be sure to use the proper size

bolts to install the motor (not included). The belts

and belt cover (not included) must be strong

enough to prevent breaking and possible injury.

8.

Be sure all equipment is rated to the

appropriate capacity of this pump.

Make sure

that the lowest rated piece of equipment being

used can handle the maximum pressure of the

Air Compressor Pump (see Specifications).

9.

Do not direct the air stream at

any person or animal.

10.

Avoid burns.

The Cylinders (13, 62), Cylinder

Heads (3, 53) and Air Outlet components become

very hot during operation. Do not touch.

11. Industrial applications must follow OSHA guidelines.

12. Maintain labels and nameplates on the

Compressor Pump. These carry important safety

information. If unreadable or missing, contact

Harbor Freight Tools for a replacement.

13. This product is not a toy.

Keep it out of reach of children.

14. WARNING: The brass components of

this product contain lead, a chemical

known to the State of California to cause

birth defects (or other reproductive harm).

(California Health & Safety code § 25249.5,

et seq.

)

Summary of Contents for 60754

Page 1: ......