Page 15

For technical questions, please call 1-888-866-5797.

Item 62913

SAFETY

Op

ERA

TION

M

AINTENANCE

INST

ALLA

TION

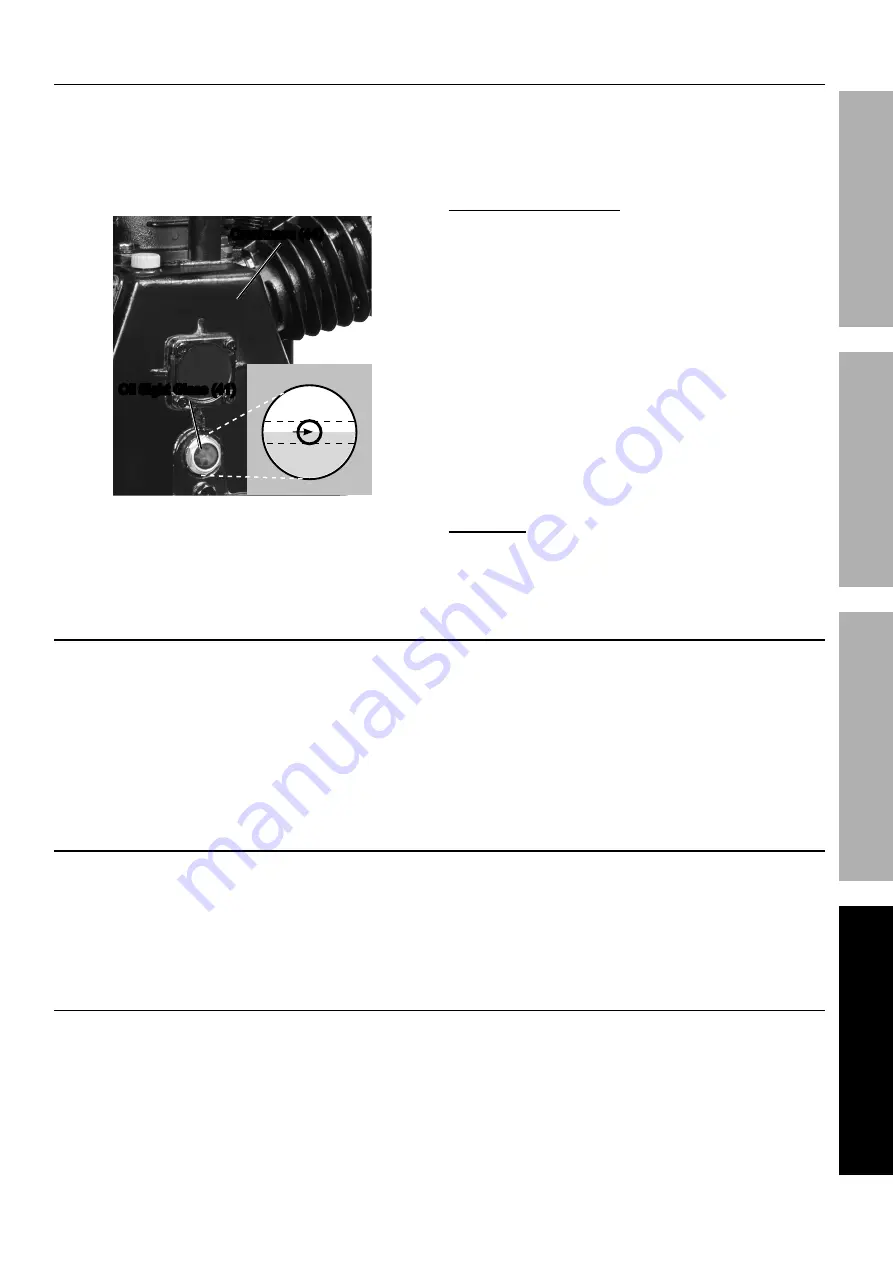

Adding Oil

1. The oil level should be at the center of the “full” level

on the Oil Sight Glass, as shown above. Add oil as

needed to maintain this level. Do not let the oil level

go below the center dot (LOW as shown below) and

do not overfill the oil so that it is above the center dot

(OVERFILL as shown below) on the Oil Sight Glass.

Oil Sight Glass (41)

Crankcase (44)

OVERFILL

LOW

FULL

OIL LEVEL

2. To add oil:

a. Remove the Oil Plug (46).

b. Using a funnel to avoid spills, pour enough

oil into the pump Crankcase to reach

the “full” level in the Oil Sight Glass.

c. Replace the Oil Plug.

Cold Weather Operation

Premium quality 30-weight, non-detergent air

compressor oil (sold separately) is recommended

for use with this compressor. Start compressor in

heated area if outdoor temperatures drop below

32° F. If this is not practical, drain out the old

pump oil and use L-PAB100-150 Non-detergent

Air Compressor Oil in the pump crankcase instead

whenever the compressor’s temperature will fall

below 40°. Do not use multi-viscosity oil (such

as 10W-30), they leave carbon deposits on pump

components and lead to accelerated failure. Heavy

operation may require heavier viscosity oil.

3. If uncertain which oil to use for this compressor,

please call Harbor Freight Tools customer

service at 1-888-866-5797 for assistance.

WARNING!

To prevent serious injury from burns:

Do not add or change the oil while

the compressor is in operation.

Allow the compressor to cool before replacing oil.

Changing Oil

1. Place a container under the Drain Plug.

2. Remove the Oil Plug to allow air flow into the Pump.

3. Remove the Drain Plug, allowing the

oil to drain into the container.

4. When the oil is completely drained from

the Pump, replace the Drain Plug.

5. Fill the Pump with new compressor oil to

the FULL level on the Oil Sight Glass.

6. Replace and tighten the Oil Plug.

7. Discard the old oil according to local,

state and federal regulations.

Draining Moisture from the Tank

The Moisture Drain is located under the Tank.

It must be used daily to release all trapped air and

moisture from the Tank. Doing this will eliminate

condensation and prevent tank corrosion.

1. Turn the Power Switch of the compressor off.

2. Place a collection pan under the Moisture Drain.

3. Open the Moisture Drain two or three turns ONLY.

4. When all the pressure and moisture is released,

close the Moisture Drain.

Air Filter Maintenance

Check the Air Filter weekly to see if it needs

replacement. If working in dirty environments,

you may need to replace the filter more

often. To replace the Air Filter:

1. Unthread the Wing Nut holding the

Muffler Assembly in place.

2. Remove the Muffler Assembly.

3. Replace with a new Air Filter.

4. Secure in place with the Wing Nut.