Page 16

For technical questions, please call 1-888-866-5797.

Item 62913

SAFETY

Op

ERA

TION

M

AINTENANCE

INST

ALLA

TION

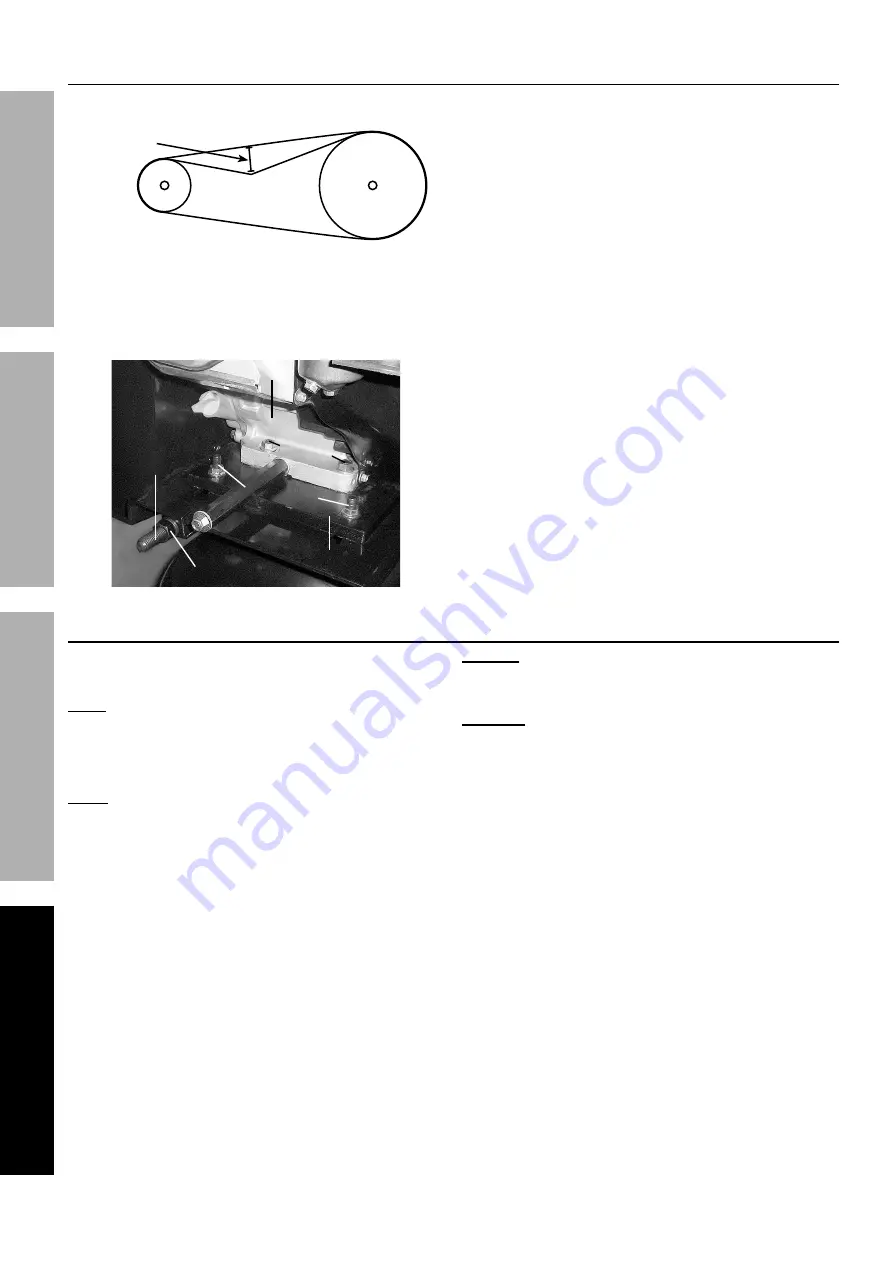

Adjusting Belt Tension

1. Remove the Belt Guard Cover (97) and set it aside.

Deflection

Distance

2. Press on the center of the longest span on each belt

with moderate finger pressure (4-4.5 lb.).

Then measure the deflection distance,

the distance that the belt moved.

The belt should deflect anywhere from 1/2″ to 1″.

Bottom Plate (85)

Nut (84)

Threaded Rod

(80)

Bolts (79)

Engine

Mounting

Bolts

Engine Base

3.

If either belt deflects too much,

tighten belts

by loosening the four Bolts (79) on the Bottom

Plate (85) and moving the engine away from the

other pulley slightly by turning the Nut (84) holding

the Threaded Rod (80). Secure engine mounting

bolts and retest tension. If either belt is too long to

be properly tensioned, both belts must be replaced.

4.

If either belt deflects too little,

loosen belts

by loosening the Bolts on the Bottom Plate and

moving the engine towards the other pulley slightly

by turning the Nut (84) on the Threaded Rod (80).

Secure engine mounting bolts and retest tension.

5. Before use, replace belt cover.

Maintenance Schedule

Following are general guidelines for

maintenance checks of the Air Compressor.

Note:

The environment in which the compressor

is used, and the frequency of use will affect how

often you will need to check the Air Compressor

components and perform maintenance procedures.

Daily:

a. Make sure all nuts and bolts are tight.

b. Drain moisture from air tank.

c. Check for abnormal noise or vibration.

d. Check for air leaks.

*

e. Wipe off any oil or dirt from the compressor.

**

Weekly:

a. Inspect Air Filter.

Monthly:

a. Inspect Safety Valve.

* To check for air leaks, apply soapy water to joints while

the Air Compressor is pressurized. Look for air bubbles.

** To clean the compressor surface, wipe with

a damp cloth, using a mild detergent or mild solvent.