Page 18

For technical questions, please call 1-888-866-5797.

Item 62913

SAFETY

Op

ERA

TION

M

AINTENANCE

INST

ALLA

TION

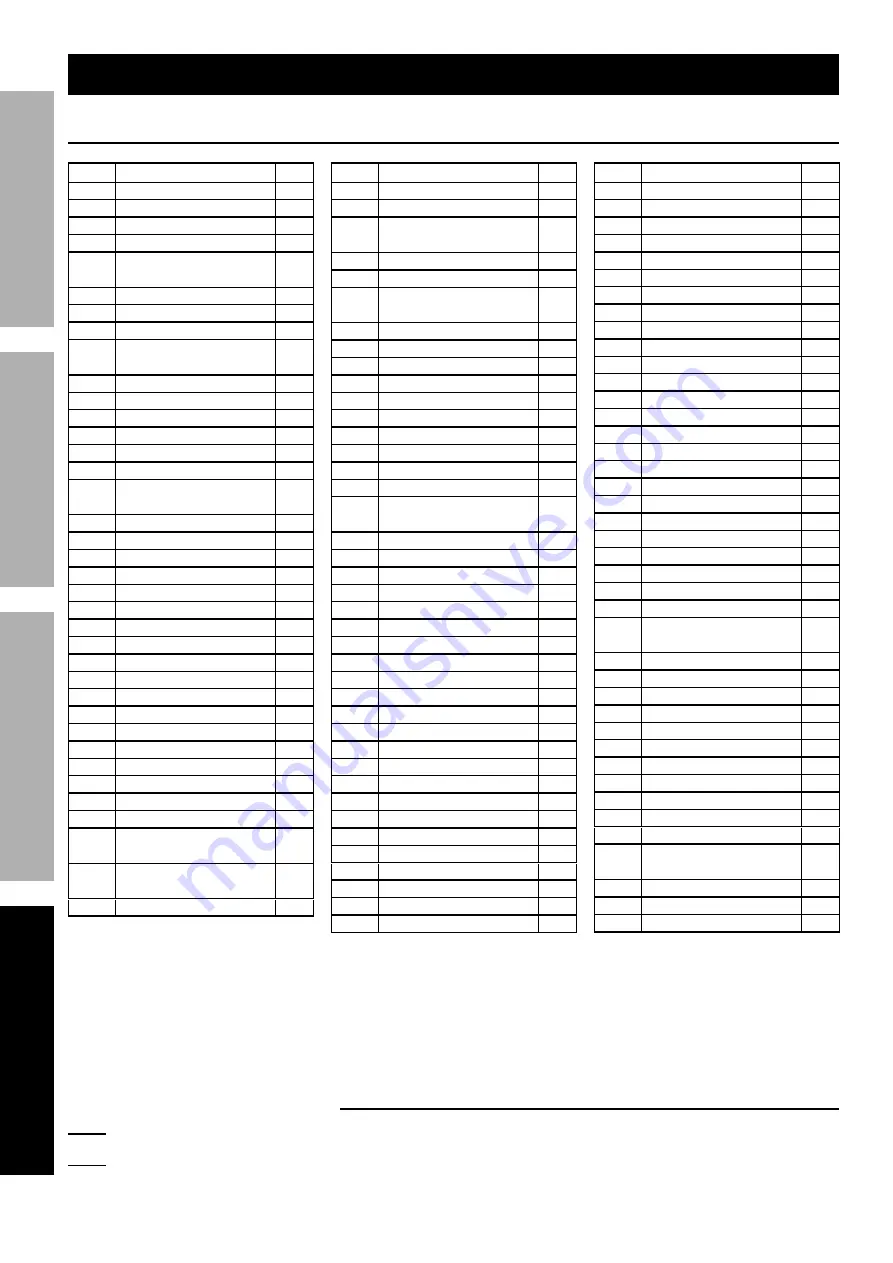

part

Description

Qty

1

Exhaust Elbow

3

2

Spring Washer

8

3

Bolts M10×50

8

4

Tube

1

5

First Stage Cylinder

Head (Iron)

2

6

Safety Valve

1

7

T-Type Exhaust Tee

1

8

Muffler

2

8-1 Muffler Aluminium

Joint

1

8-2 Muffler Gasket

1

8-3 Muffler Seat

1

8-4 Air Filter

1

8-5 Muffler Cover

1

8-6 Flat Washer

1

8-7 Wing Nut M6

1

9

Cylinder Head

Sealing Gasket

2

10 Valve Plate Assembly

2

10-1 Bolt M5×12

2

10-2 Spring Washer

2

10-3 Lift Limiter

1

10-4 Exhaust Valve Piece

1

10-5 Valve Plate

1

10-6 Intake Valve Slice

1

10-7 Cylindrical Pin Ø3×8

2

10-8 Spring Sheet

1

11 Valve Plate Seal

2

12 Bolts M10×25

12

13 Spring Washer

25

14 Cylinder

2

15 Cylinder Seal

3

16 Piston Ring Ø90

2

17 Hole Circlip Ø20

4

18 Piston Pin Ø20×80

2

19 Piston (Aluminum)

2

20 Connecting Rod

(Oblique)

1

21 Connecting Rod

(Straight)

1

22 Tube

1

part

Description

Qty

23 Bolts M8×50

4

24 Spring Washer

4

25 Second Stage

Cylinder Head

1

26 Cylinder Head Gasket

1

27 Valve Plate

2

28 Valve Plate

Aluminum Seal

1

29 Valves

2

30 Valve Plate Seal

1

31 Cylinder

1

32 Piston Ring

1

33 Hole Circlip

2

34 Piston (Iron)

1

35 Piston Pin

1

36 Connecting Rod

1

37 Bolts M6×20

4

38 Spring Washer

4

39 Small Square

Back Cover

1

40 Back Cover Gasket

1

41 Oil Sight Glass

1

42 Oil Sight Gasket

1

43 Drain Plug

1

44 Crankcase

1

45 Oil Plug Seal

1

46 Oil Plug

1

47 Bearing

1

48 Shaft Circlips Ø30

1

49 Shoulder Ring

1

50 Crankshaft

1

51 Woodruff Key

1

52 Bearing

1

53 Oil Seal

1

54 Front Cover Gasket

1

55 Front Cover

1

56 Breathing Gasket

1

57 Connecting Rod (Iron)

1

58 Breathing

1

59 Spring Washer

6

60 Bolt M8×25

6

61 Belt Pulley

1

62 Pulley Retaining Ring

1

part

Description

Qty

63 Bolt M10×35

1

64 Exhaust Tube

1

65 Air Outlet

1

66 Tank

1

67 Drain Valve

1

68 Nut M10

12

69 Flat Washer

12

70 Bolt M10×35

4

71 Combination Valve

1

72 Elbow

1

73 Unloading Tube

1

74 Throttle Push Rod

1

75 Safety Valve

1

76 Tank Pressure Gauge

1

77 Copper Tee

1

78 Wiring Stake

2

79 Bolt M10×35

4

80 Threaded Rod

1

81 Tense Card

1

82 Flat Washer

1

83 Spring Washer

1

84 Nut M12

1

85 Bottom Plate

1

86 Socket Cap Screw

4

87 Gasoline Engine

1

88 Gasoline Engine

Pulley

1

89 Pulley Retainer Ring

1

90 Spring Washer

1

91 Bolt 3/8″×1-1/2

1

92 V-Belt

2

93 Belt Guard Frame

1

94 Flat Washer

13

95 Spring Washer

13

96 Bolt M8×20

13

97 Belt Guard Cover

1

98 Belt Guard Bracket

1

99 Bolt M6×16

1

100 Standard Spring

Washer

1

101 Flat Washer

1

102 Nut

1

103 Belt Guard Bracket

1

parts List and Diagram

parts List

Record product’s Serial Number Here:

Note:

If product has no serial number, record month and year of purchase instead.

Note:

Some parts are listed and shown for illustration purposes only,

and are not available individually as replacement parts.