Page 7

For technical questions, please call 1-888-866-5797.

Item 62913

SAFETY

Op

ERA

TION

M

AINTENANCE

INST

ALLA

TION

Installation

Read the ENTIRE IMpORTANT SAFETY INFORMATION section at the beginning of this

manual including all text under subheadings therein before set up or use of this product.

The emission control system for this Compressor’s Engine is warranted for standards set

by the U.S. Environmental Protection Agency and by the California Air Resources Board

(also known as CARB). For warranty information, refer to the engine manual.

Note:

For additional information regarding the parts listed in the following pages,

refer to the Assembly Diagram near the end of this manual.

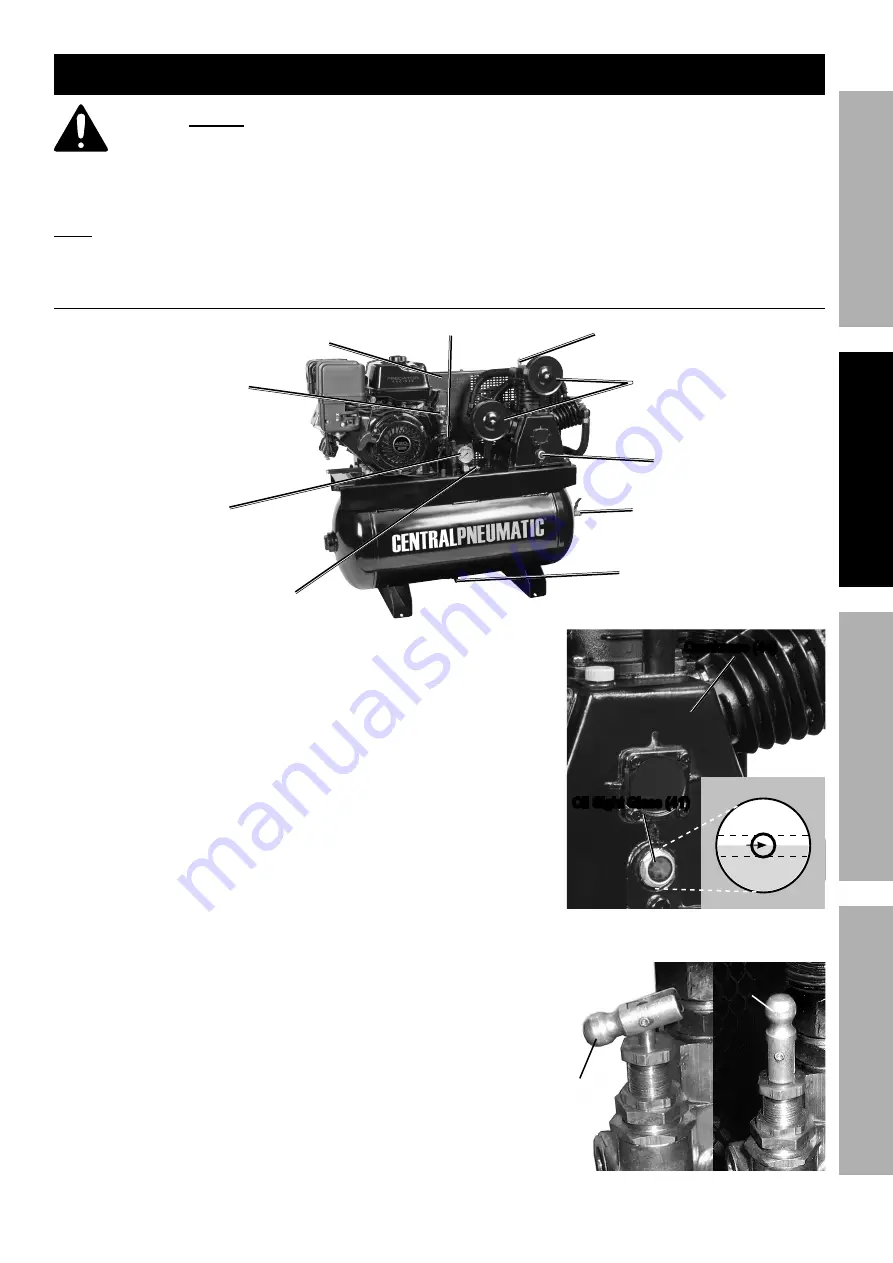

Functions

ON/OFF

Switch

Tank

pressure

Gauge (76)

Tank Safety Valve (75)

pilot Valve

Air Outlet (65)

Drain Valve (67)

pump Safety Valve (6)

Oil Sight

Glass (41)

Belt Guard Frame (93) &

Belt Guard Cover (97)

Muffler

Assembly (8)

1.

Belt Guard

- The Belt Guard encloses the pulleys and drive belts.

It protects the user from the moving parts and allows the

large pulley to direct cooling air to the Air Pump.

2.

Oil Sight Glass -

The oil sight glass shows proper level of

the oil. Oil level should be at center of Sight Glass.

3.

Tank Drain Valve -

The Air Tank Drain Valve allows moisture

to be removed from the tank to prevent corrosion.

4.

Safety Valve -

The Safety Valve automatically releases air if the Air

Tank pressure exceeds the preset maximum. In an emergency, the

ring can be pulled to relieve tank air pressure. There is one

safety valve on the pump and one on the tank.

5.

Air Outlet -

An air hose attaches to this valve. Air pressure required by

tools is set by an air pressure regulator.

6.

Air Storage Tank -

The Air Tank is where air

pressurized by the Air Pump is stored for use.

7.

Tank pressure Gauge -

The Air Tank Pressure

Gauge displays the air pressure in the tank.

8.

pilot Valve -

Open the Pilot Valve before starting the engine.

It relieves resistance on the engine to make starting possible.

Rotate the pin so it is vertical to open it. Once the engine is running,

close the Pilot Valve so the Compressor can build up pressure.

Oil Sight Glass (41)

Crankcase (44)

OVERFILL

LOW

FULL

OIL LEVEL

Closed

Pilot Valve

Opened

Pilot Valve