SKU 65903

For technical questions, please call 1-800-444-3353.

Page 10

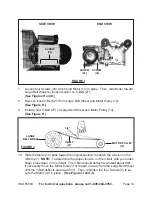

Turn the Pressure Adjustment Knob (6)

4.

counterclockwise

all the way to its

“OFF”

position.

(See Figure E.)

Turn Lever on Air Outlet Valve (4) backward to

5.

closed

position.

(See Figure E.)

Attach an air hose (not included) to Air Outlet Valve. Then, attach the other end of

6.

the air hose to the pneumatic tool that will be used.

(See Figure E.)

To Start The Air Compressor:

Plug the Power Cord Plug (31) into the nearest 240 volt, grounded, electrical out-

1.

let.

Rotate the Power Switch Lever (9) up to its

2.

“ON”

position.

(See Figure E.)

Turn the Pressure Adjustment Knob (6)

3.

clockwise

about halfway to its

“ON”

posi-

tion.

(See Figure E.)

Allow sufficient time for Tank Pressure Gauge (5A) to indicate at least

4.

80 PSi

.

(See Figure E.)

Check to make sure the pneumatic tool which will be used is turned off and prop-

5.

erly connected to air hose.

Once the Tank Pressure Gauge (5A) has reached at least 80 PSI, turn the Lever

6.

on the Air Outlet Valve (4) forward to its

open

position in order to supply air to the

pneumatic tool.

(See Figure E.)

If necessary, turn the Pressure Adjustment Knob (6)

7.

clockwise

to increase air

pressure to the pneumatic tool or

counterclockwise

to decrease air pressure to the

pneumatic tool. The Outlet Pressure Gauge (5) shows the air pressure being sup-

plied to the tool.

(See Figure E.)

To use The Air Tank Safety Release Valve:

The Safety Release Valve (3) is used when decompression is needed quickly and

1.

efficiently.

(See Figure E.)

To decompress the Air Tank (32) pressure, rotate the Power Switch Lever (9) to the

2.

OFF position to turn off the Air Compressor.

(See Figure E.)

Pull out on the Safety Release Valve Ring (3) to immediately release air pressure

3.

in the Air Tank (32).

(See Figure E.)

To use The Overload Reset button:

The Air Compressor is equipped with an internal electrical circuit breaker which is

1.

designed to automatically shut off the Air Compressor in the event its Motor (14)

becomes overheated.

(See Figure E.)

Should the Air Compressor automatically shut off at a pressure less than 115 PSI,

2.

rotate the Power Switch Lever (9) down to its

“OFF”

position.

(See Figure E.)