SKU 65903

For technical questions, please call 1-800-444-3353.

Page 12

iNSPECTiON, MAiNTENANCE, ANd CLEANiNG

1.

WARNiNG!

Always make sure the Power Switch Lever (9) is in its “OFF”

position, the Air Compressor is disconnected from its electrical outlet, and

all remaining compressed air is expelled from the system before performing

any inspection, maintenance, or cleaning.

before each use:

2.

Inspect the general condition of the Air Compressor. Check for

misalignment or binding of moving parts, cracked or broken parts, loose or dam-

aged connections, and any other condition that may affect its safe operation. If

abnormal noise or vibration occurs, have the problem corrected before further use.

do not use damaged equipment.

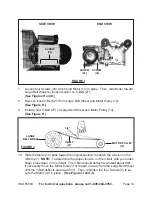

FiGuRE F

OiL FiLL HOLE

PCV FiLTER

(41)

OiL FiLL CAP

(28)

3.

before each use:

Make sure to fill the Air Compressor with a premium quality,

30

weight, non-detergent oil.

Running the Air Compressor with no oil or low oil will

cause damage to the equipment and void its warranty. When filling the Air Com

-

pressor with oil, make sure to

unscrew

(do not pull) the Oil Fill Cap (28) to remove.

Fill with oil until the level of the oil rises to the midway point in the Oil Level Indica-

tor (35). Then, screw the Oil Fill Cap back onto the Oil Fill Hole.

NOTE: When the

Compressor is running, some oil will escape the Oil Fill Cap bleeder; this is a

normal occurance. Periodically clean up this oil overflow.

(See Figure F.)

NOTE:

4.

Each time the Oil Fill Cap (28) is removed, observe the PCV Filter (41)

that is located inside the Oil Fill Cap. When necessary, remove the PCV Filter and

clean with a mild solvent. Allow the PCV Filter to dry. Then, replace the PCV Filter

REV 09b