SKU 65903

For technical questions, please call 1-800-444-3353.

Page 5

SPECiFiC SAFETY RuLES

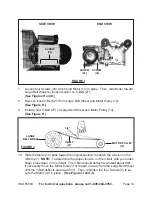

CAuTiON! Prior to its

1.

first

use, and thereafter prior to each

subsequent

use,

make sure to fill the Air Compressor with a premium quality, 30 weight, non-

detergent oil to the specified level.

Running the Air Compressor with no oil or

with low oil will cause damage to the equipment and void its warranty. Refer to the

“Operating Instructions”

section for details on filling the Air Compressor with oil.

When filling the Air Compressor with oil, make sure to

2.

unscrew

(do not pull)

the Oil Fill Cap to remove.

use eye and ear protection.

3.

Always wear ANSI-approved safety impact eye

goggles, and ear plugs when using the Air Compressor.

Make sure all tools and equipment used with the Air Compressor are rated to

4.

the appropriate air pressure capacity of the Air Compressor.

Do not use any

tool or equipment that does not operate from 0-115 PSI. If necessary, check the

owner’s manual of the tool or equipment for its air pressure rating.

Always disconnect the Air Compressor from its electrical outlet, release any

5.

remaining air pressure from the unit, and disconnect all pneumatic tools and

equipment from the unit, before performing any services or maintenance.

Avoid injury. Never direct the air jet at people or animals.

6.

inspect safety valve daily

7.

. If the safety valve is not working properly, tank pres-

sure can build up to dangerous levels. The tank could explode. For this reason,

pull the ring on the safety valve before each use and verify that it operates freely.

Replace safety valve if it does not operate freely.

Never remove or alter the factory sealed Safety Release Valve.

do not attempt to readjust the automatic start and shutoff valves.

8.

Any

change to the automatic ON/OFF pressure levels will cause additional stress on

the motor, which may result in shortened motor life.

drain the Air Compressor’s air tank every day.

9.

Do not allow moisture to build

up inside the Air Tank.

do not unscrew the tank drain valve so that

10.

more than

four threads are

showing.

Avoid risk of tank explosion

11.

.

Avoid weakening of tank by draining condensation after each use.

a.

Never modify tank by drilling holes, welding to it, or modifying it’s parts.

b.

The tank is designed, and factory set, to operate within a specific pressure range.

c.

For that reason, never make adjustments to, or substitute parts, to the compres-

sor.

Avoid bodily injury from moving parts

12.

. The compressor cycles on automatically,

without notice. For this reason, always keep hands and arms away from compres-