Page 5

For technical questions, please call 1-800-444-3353.

SKU 67708

5.

do not leave compressor unattended

for an extended period while plugged

in. unplug compressor after working.

6.

keep compressor well-ventilated. do

not cover compressor during use.

7. Drain Tank daily and after use. Internal

rust causes tank failure and explosion.

8. Add correct amount of compressor

oil before first use and every use.

Operating with low or no oil causes

permanent damage and voids warranty.

9. Do not remove the valve cover or adjust

internal components.

10. Compressor head gets hot during

operation. Do not touch it or allow

children nearby during or immediately

following operation.

11. Do not use the air hose to move the

compressor.

12. Release the pressure in the storage tank

before moving.

13. The use of accessories or attachments

not recommended by the manufacturer

may result in a risk of injury to persons.

14. All air line components, including hoses,

pipe, connectors, filters, etc., must be

rated for a minimum working pressure

of 150 PSI, or 150% of the maximum

system pressure, whichever is greater.

15. USE OF AN EXTENSION CORD IS NOT

RECOMMENDED. If you choose to

use an extension cord, use the following

guidelines:

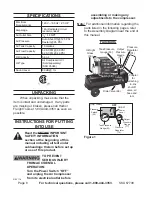

recommended mInImum WIre

GauGe For eXtenSIon cordS

(120 Volt)

namePlate

amPereS

(at full load)

eXtenSIon cord

lenGtH

25’

50’ 100’ 150’

0 – 6

18

16

16

14

6.1 – 10

18

16

do not use.

10.1 – 12

16

16

do not use.

12.1 – 16

14

12

do not use.

table a

a. Make sure your extension cord is in

good condition.

b. Be sure to use an extension cord

which is heavy enough to carry the

current your product will draw. An

undersized cord will cause a drop in line

voltage resulting in loss of power and

overheating. Table A shows the correct

size to use depending on cord length

and nameplate ampere rating. If in

doubt, use the next heavier gauge. The

smaller the gauge number, the heavier

the cord.

16. Industrial applications must follow OSHA

guidelines.

17. Maintain labels and nameplates on the

compressor. These carry important

safety information. If unreadable or

missing, contact Harbor Freight Tools for

a replacement.

18. This product is not a toy. Keep it out of

reach of children.

19. Operate unit on level surface. Check

oil level daily and fill to marked level if

needed.