Page 8

For technical questions, please call 1-800-444-3353.

SKU 67708

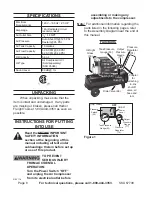

SPecIFIcatIonS

Electrical

Requirements

120 V~ / 60 Hz / 2.5 HP

Amperage

14A (Dedicated circuit

recommended)

Air Outlet Size

1

/

4

” -18 NPT

Air Pressure

Auto Shut-Off @ 125 PSI

Restart @ 95 PSI

Air Tank Capacity

10 Gallons

Air Flow Capacity

5.3 SCFM @ 90 PSI

6.2 SCFM @ 40 PSI

Oil Capacity

5.6 oz.

Oil Type

Air Compressor Oil

(Sold separately)

(SKU 95048)

Sound Level

89 dB @ 1m

unPackInG

When unpacking, make sure that the

item is intact and undamaged. If any parts

are missing or broken, please call Harbor

Freight Tools at 1-800-444-3353 as soon as

possible.

InStructIonS For PuttInG

Into uSe

read the entIre ImPortant

SaFetY InFormatIon

section at the beginning of this

manual including all text under

subheadings therein before set up

or use of this product.

to PreVent

SerIouS InjurY

From accIdental

oPeratIon:

turn the Power Switch “oFF”

and unplug the air compressor

from its electrical outlet before

assembling or making any

adjustments to the compressor.

note:

For additional information regarding the

parts listed in the following pages, refer

to the Assembly Diagram near the end of

this manual.

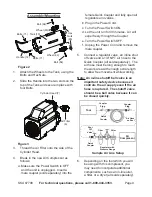

Functions

Figure 1

ON/OFF

Power

Lever

(On

Pressure

Switch (54))

Oil Sight

Glass

(33)

Pressure

Regulator

(74)

Safety

Valve (73)

Tank Pressure

Gauge (53)

Output

Pressure

Gauge

(77)

Coupler

for

attaching

in-line

shutoff

valve, air

hose and

tool

Drain Valve (66)

oFF

on

ON/OFF

Power

Lever

Tank Pressure

Gauge (53)

Output

Pressure

Gauge

(77)

Pressure

Regulator

(74)

Pressure

Switch

(54)

(Top View)

REV 11b