Page 9

For technical questions, please call 1-800-444-3353.

SKU 67708

assembly/mounting

1.

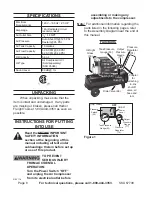

Figure 2

Bolt (64)

Bolt (64)

Hex

Nuts

(65)

Handle (72)

Bolts (71)

Bolts (71)

Tank (70)

Wheel (63)

Wheel (63)

Attach the Wheels to the Tank, using the

Bolts and Hex Nuts.

2. Slide the Handle into the two slots on the

top of the Tank and secure in place with

four Bolts.

3.

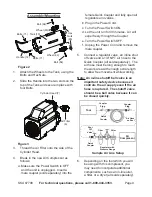

Figure 3

Air Filter

(6)

Cylinder Head (7)

Thread the Air Filter onto the side of the

Cylinder Head.

4. Break in the new Air Compressor as

follows:

a. Make sure the Power Switch is OFF

and the unit is unplugged. Insert a

male coupler (sold separately) into the

female Quick Coupler and fully open all

regulators and valves.

b. Plug in the Power Cord.

c. Turn the Power Switch ON.

d. Let the unit run for 30 minutes. Air will

expel freely through the Coupler.

e. Turn the Power Switch OFF.

f. Unplug the Power Cord and remove the

male coupler.

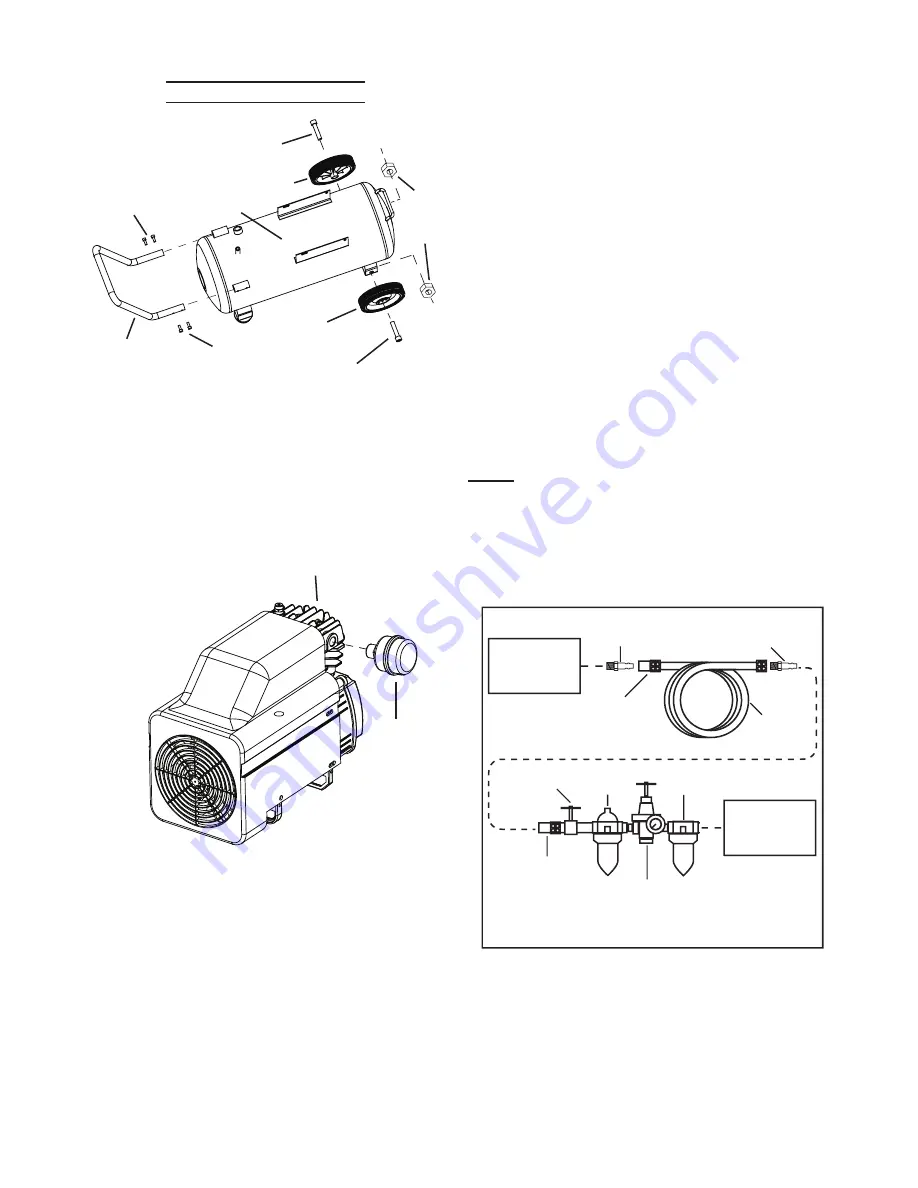

5. Connect a regulator valve, an inline shut

off valve and a 1/4” NPT air hose to the

Quick Coupler (all sold separately). The

air hose must be long enough to reach

the work area with enough extra length

to allow free movement while working.

note:

an in-line shutoff ball valve is an

important safety device because it

controls the air supply even if the air

hose is ruptured. the shutoff valve

should be a ball valve because it can

be closed quickly.

6.

Quick

coupler

Sample air line Setup

regulator with

Pressure Gauge

Quick

coupler

air Hose

on reel

Shut

off

Valve

Filter

oiler

coupler

Plug

tool

air

compressor

coupler

Plug

Depending on the tool which you will

be using with this compressor, you

may need to incorporate additional

components, such as an in-line oiler,

a filter, or a dryer (all sold separately).