This unit was fully tested and inspected prior to shipment and will operate properly when instructions are followed. Refer to your owner’s manual for basic

troubleshooting.

To avoid unnecessary return to the store, simply call Compressor Support toll free for additional assistance.

DO NOT RETURN TO STORE

IMPORTANT

STOP

STOP

Compressor Support:

1-888-866-5797

• Air Compressor will automatically shut off when maximum PSI is reached. When the tank pressure drops to the cut in pressure (low pressure) and

the on/off switch is in the ON position, the unit will automatically restart.

• On occasion, maximum pressure in tank will remain until next use thus resulting in a sense of no power (See bullet above).

• To avoid power loss, overheating and ensure power, use additional air hose rather than extension cords.

• It is the consumer’s responsibility to drain oil lubricated units prior to shipment to meet ICC, state and local fire regulations.

Please have your model number and serial number available. These can be found on the data label on your product. Retain a copy of your

receipt with purchase date for reference.

NOTICE

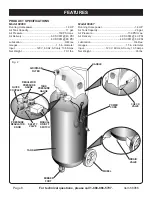

This tool has many features for making its use more pleasant and enjoyable. Safety, performance, and dependability

have been given top priority in the design of this product making it easy to maintain and operate.

Safety ...............................................................................................................................................................................3

Features ...........................................................................................................................................................................8

Assembly ..........................................................................................................................................................................9

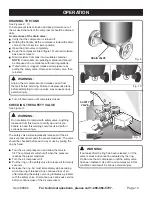

Operation ........................................................................................................................................................................12

Maintenance ...................................................................................................................................................................14

Troubleshooting ..............................................................................................................................................................15

Warranty .........................................................................................................................................................................16

TABLE OF CONTENTS

INTRODUCTION

DANGER

This compressor/pump is not equipped and should not be used to supply breathing quality air. Additional equipment

would be necessary to properly filter and purify the air to meet minimal specifications for Grade D breathing as

described in Compressed Gas Association Commodity Specification G 7.1 - 1966, OSHA 29 CFR 1910.134.

Compressed Gas Association, 4221 Walney Road, Fifth Floor, Chantilly, VA 20151-2923, (703) 788-2700,

www.cganet.com. Any such additional equipment has not been examined and no implication of proper use for

breathing air is intended or implied.

If this compressor is altered in any way, existing warranties shall be voided. Harbor Freight Tools disclaims any

liabilities whatsoever for any loss, personal injury, or damage.

Page 2

For technical questions, please call 1-888-866-5797.

Item 68066