11

PRESSURE VESSELS

Air receiver tanks and other pressure containing vessels

must be equipped with a properly sized pressure relief

valve, pressure gauge, and a tank drain. The drain valve

must be located in the bottom of the air tank(s) to provide

for moisture removal.

TANK PRESSURE GAUGE

The tank pressure gauge indicates the pressure of the air

in the tank.

FEATURES

When using the compressor for spray painting, isolate the

compressor as far away from the work area as practical,

employing extra air hose rather than an extension cord.

Warranty will be void if a failure is determined to be caused

by dust, dirt or other contaminants.

COMPRESSED AIR DISCHARGE SYSTEM

WARNING!

Discharge piping can exceed 350°F when compressor

is operating. Do not use plastic pipe or lead tin soldered

joints for a discharge line. Do not modify the discharge

line.

WARNING!

Pressure vessels must not be modified, welded on, or

repaired. Such actions may cause property damage,

severe injury, or even death.

ASSEMBLY

UNPACKING

This product has been shipped completely assembled,

except the four rubber feet.

Carefully remove the compressor from the box. Make

sure that all items listed in the packing list are included.

Inspect the compressor carefully to make sure no

breakage or damage occurred during shipping.

Do not discard the packing material until you have

carefully inspected and satisfactorily operated the tool.

If any parts are damaged or missing, please call

1-800-444-3353 for assistance.

PACKING LIST

Air Compressor (1)

Operator’s Manual (1)

Replacement Parts List (1)

INSTALLATION

Air compressors should be located in an area that is dry,

clean, well lighted, and adequately ventilated.

Air supplied to the inlet filter must be clean. The compressor

belt guard must not be located closer than 12 inches to a

wall, or 24 inches to another compressor. Additional safety

can be achieved by locating the pulley drive system, with

the guard, next to the wall.

The compressor may only be operated in temperatures

under 104°F and over 32°F. In cold climates, the compressor

should be installed in a heated building.

Proper mounting of the compressor unit is crucial to the safe

operation and longevity of the equipment. The installation

requires a stable, flat and level surface. Satisfactory results

can usually be obtained by mounting the compressor

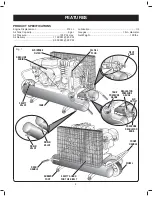

unit on rubber feet supplied with the unit. Refer to

Fig. 2

.

Uneven feet drawn tightly to a concrete floor or truck bed

will cause severe vibrations resulting in cracked welds or

fatigue failure.

If the unit is mounted to a concrete floor

or truck bed or similar foundation, loosen the lock nut

several turns & lock it with a back-up nut!

The customer

WARNING:

If any parts are missing do not operate the compressor

or air tools until the missing parts are replaced. Failure

to do so could result in possible serious personal injury.

WARNING:

Do not attempt to modify this tool or create accessories

not recommended for use with this tool. Any such

alteration or modification is misuse and could result

in a hazardous condition leading to possible serious

personal injury.

DANGER!

A gas engine will produce carbon monoxide; always

provide adequate ventilation! Do not operate engine

in an enclosed area.

.