13

Turn off drain valve until completely closed.

CHECKING THE SAFETY VALVE

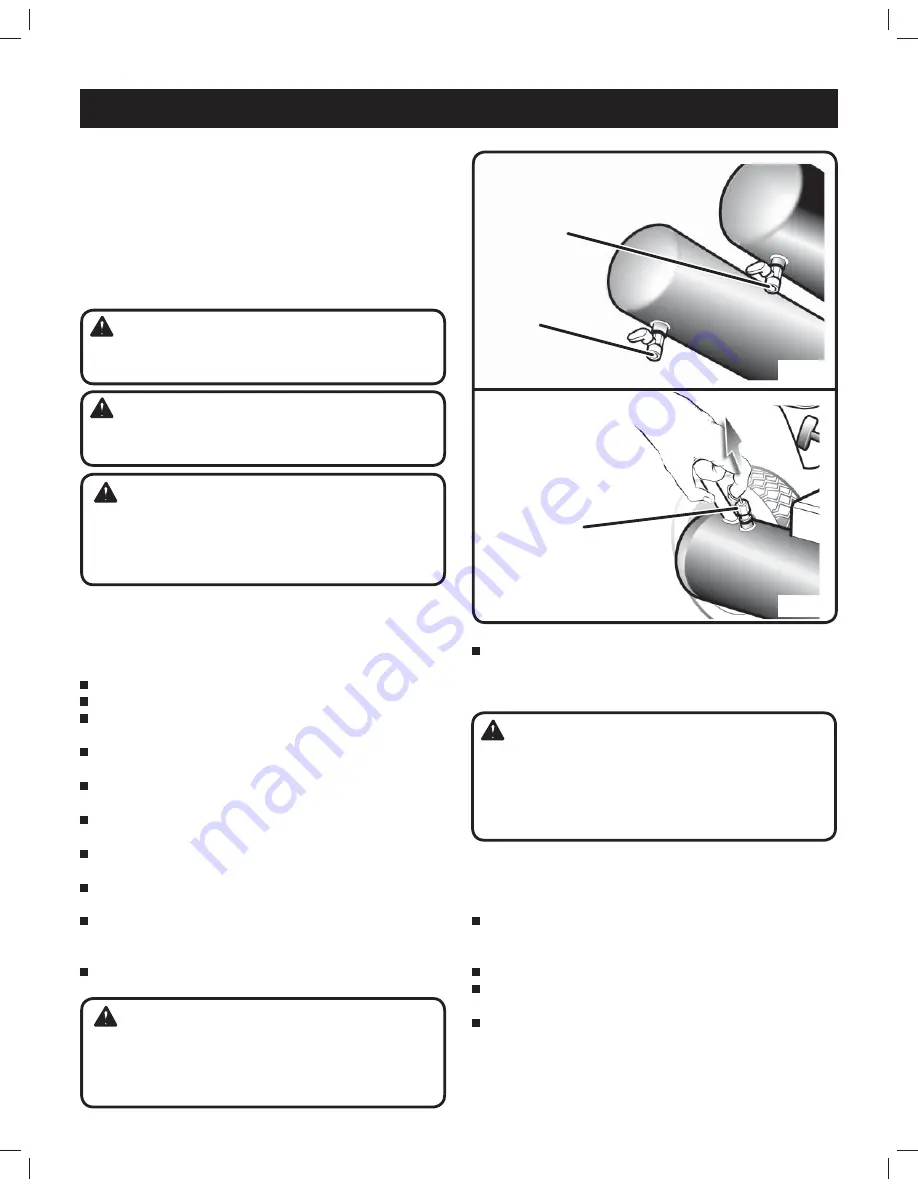

See Figure 4.

The safety valve will automatically release air if the air receiver

pressure exceeds the preset maximum. The valve should be

checked before each day of use by pulling the ring by hand.

Turn the air compressor on and allow the tank to

fill. The compressor will shut off when the pressure

reaches the preset maximum.

Turn the air compressor off.

Pull the ring on the safety valve to release air for twenty

seconds.

Release the ring. Air must immediately stop escaping

when the ring is released. Any continued loss of air

after releasing the safety valve ring indicates a problem

with the safety valve. Discontinue use and seek service

before continued use of the air compressor.

WARNING:

If air leaks after the ring has been released, or if the

valve is stuck and cannot be actuated by the ring,

Do Not use the air compressor until the safety valve

has been replaced. Use of the air compressor in this

condition could result in serious personal injury.

DRAINING THE TANK

See Figure 3.

The drain valve is located on the underside of each air

tank(s). The compressor can be tilted in the direction of the

drain valve in order to allow removal of tank moisture.

To help prevent tank(s) corrosion and keep moisture out

of the air used, the tank(s) of the compressor should be

drained daily.

Tank(s) subjected to freezing temperatures may contain

ice. Store the compressor in a heated area before

attempting to drain moisture from the tank(s).

A correct use of the drain valve:

Verify that the compressor is turned off.

Disconnect the spark plug wire from the spark plug.

Reduce the air pressure in the tank to 30 PSI by pulling

the safety valve ring (Fig. 4).

Position yourself so that the moisture and air to be

expelled can not cause you harm.

Holding the handle, tilt the compressor toward the drain

valve so that it’s set in a lower position.

Open the drain valve completely, allowing the moisture

and air mixture to drain from the tank.

Keep the compressor tilted until all moisture has been

removed.

Once the moisture has been completely drained, close

the drain valve.

Drain moisture from tank into a suitable container.

NOTE:

Condensate is a polluting material and should

be disposed of in compliance with local regulations.

If drain valve is clogged, release all air pressure by pulling

the safety valve. Remove and clean valve, then reinstall.

OPERATION

WARNING:

Unplug the air compressor and release all air from

the tank before servicing. Failure to depressurize tank

before attempting to remove valve may cause serious

personal injury.

WARNING:

Do not attempt to tamper with safety valve. Anything

loosened from this device could fly up and hit you.

Failure to heed this warning could result in death or

serious personal injury.

Fig. 4

Fig. 3

WARNING!

Do not open a drain valve on any air tank containing

more than 30 PSI of air pressure!

WARNING!

Never attempt to relieve air pressure in an air tank by

removing a pipe plug or any other system component!

DRAIN

VALVE

DRAIN

VALVE

SAFETY

VALVE

(Rotate drain valve right to open)