14

Drain moisture from the air tank(s). Never attempt

to drain the tank(s) without first relieving the system

pressure (using the instruction found in

Draining the

Tank

).

STARTING & STOPPING THE COMPRESSOR

Connect the air line to the quick coupler.

Rotate regulator knob fully counterclockwise in order to

close the air flow.

Ensure both drain valves are closed.

Fill the engine with oil through oil fill hole.

Fill the compressor pump with oil. Do not overfill.

Fill the fuel tank with fuel.

Open the petcock on the unloader valve for cold starts

(turn clockwise or in).

Flip the toggle on the pilot valve to the “MANUAL

UNLOAD” position (see

Pilot Valve Adjustments

).

Start the gas engine (refer to

gas engine owner’s

manual

for more detailed start-up procedures):

– Adjust choke and open fuel valve.

– Pull the cord.

– Move choke to run.

Watch and listen for excessive vibration and unusual

noises. If either exist, stop the compressor and refer to

Troubleshooting

.

Allow the compressor to run for a few minutes.

Close the petcock (turn counterclockwise or out).

Flip the toggle on the pilot valve to the “RUN” position.

The compressor should pump up the tank to 135

PSI, then unload. If pressure exceeds 135 PSI, see

Troubleshooting

.

New compressors should be run with approximately

80 PSI of air pressure in the tank for 1 hour to break-in

(use regulator to control tank pressure). This will allow

the compressor time to warm up and seat the rings.

To stop the compressor, shut the engine off.

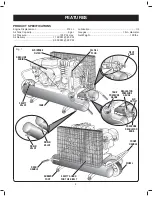

USING THE AIR COMPRESSOR

See Figure 5.

Rotate pressure regulator knob to desired line

pressure. Turning the knob clockwise increases

air pressure at the outlet; turning counterclockwise

reduces air pressure at the outlet.

APPLICATIONS

Air compressors are utilized in a variety of air system

applications. Match hoses, connectors, air tools, and

accessories to the capabilities of the air compressor.

You may use this tool for purposes listed below:

Operating some air-powered tools.

Inflating tires, air beds, sports equipment, etc.

PRE-STARTING CHECKLIST

The following steps should be performed prior to operating

the unit. If any condition of the checklist is not satisfied,

make the necessary adjustments or corrections before

starting the compressor.

WARNING:

Always wear safety goggles or safety glasses with

side shields when operating power tools. Failure to do

so could result in objects being thrown into your eyes

resulting in possible serious injury.

WARNING:

Do not allow familiarity with tools to make you careless.

Remember that a careless fraction of a second is

sufficient to inflict serious injury.

CAUTION:

Do not use in an environment that is dusty or otherwise

contaminated. Using the air compressor in this type of

environment may cause damage to the unit.

OPERATION

WARNING:

Always ensure the regulator pressure gauge read

zero before changing air tools or disconnecting the

hose from the air outlet. Failure to do so could result in

possible serious personal injury.

The compressor is shipped with lubricant in the

crankcase. Check lubricant level per specifications

(using the instruction found in

Lubrication

).

Make sure all safety valves are correctly installed.

(using the instruction found in

Features

).

Be sure all guards are in place and securely mounted

(using the instruction found in

Features

).

WARNING!

Failure to perform the PRE-STARTING CHECKLIST may

result in mechanical failure, property damage, serious

injury or even death.

WARNING!

Never assume a compressor is safe to work on just because

it is not operating. It could restart at any time. Follow all

safety precautions outlined in

MAINTENANCE

.