Page 7

For technical questions, please call 1-800-444-3353.

Item 69667

SAFETY

OPERA

TION

MAINTENANCE

SETUP

Assembly/Mounting

1. Attach the Wheels to the Tank,

using the Bolts and Hex Nuts.

2. Slide the Handle into the two slots on the top of

the Tank and secure in place with four Bolts.

3. Thread the Air Filter onto the side

of the Cylinder Head.

4.

Check and Fill oil according to section below.

5. Break in the new Air Compressor as follows:

a. Turn the Power Switch off and unplug the unit.

Insert a male coupler (sold separately)

into the female Quick Coupler and fully

open all regulators and valves.

b. Plug in the Power Cord.

c. Turn the Power Switch ON.

d. Let the unit run for 30 minutes.

Air will expel freely through the Coupler.

e. Turn the Power Switch OFF.

f. Unplug the Power Cord and

remove the male coupler.

6. Connect a regulator valve, an inline shut off valve

and a 1/4″ NPT air hose to the Quick Coupler

(all sold separately). The air hose must be long

enough to reach the work area with enough extra

length to allow free movement while working.

Note:

An in-line shutoff ball valve is an important

safety device because it controls the air supply even

if the air hose is ruptured. The shutoff valve should

be a ball valve because it can be closed quickly.

7. Depending on the tool which you will be

using with this compressor, you may need to

incorporate additional components, such as an

in-line oiler, a filter, or a dryer (all sold separately),

as shown on Figure C on page 8 and

Figure D on page 9. Consult your air

tool’s manual for needed accessories.

Checking the Oil

1. Check the oil level before operation.

Fill the Pump Crankcase with

SAE 30W, non-detergent,

Air Compressor Oil (sold separately).

IMPORTANT:

Running the Air Compressor

with no oil or low oil will cause damage to

the equipment and void the warranty.

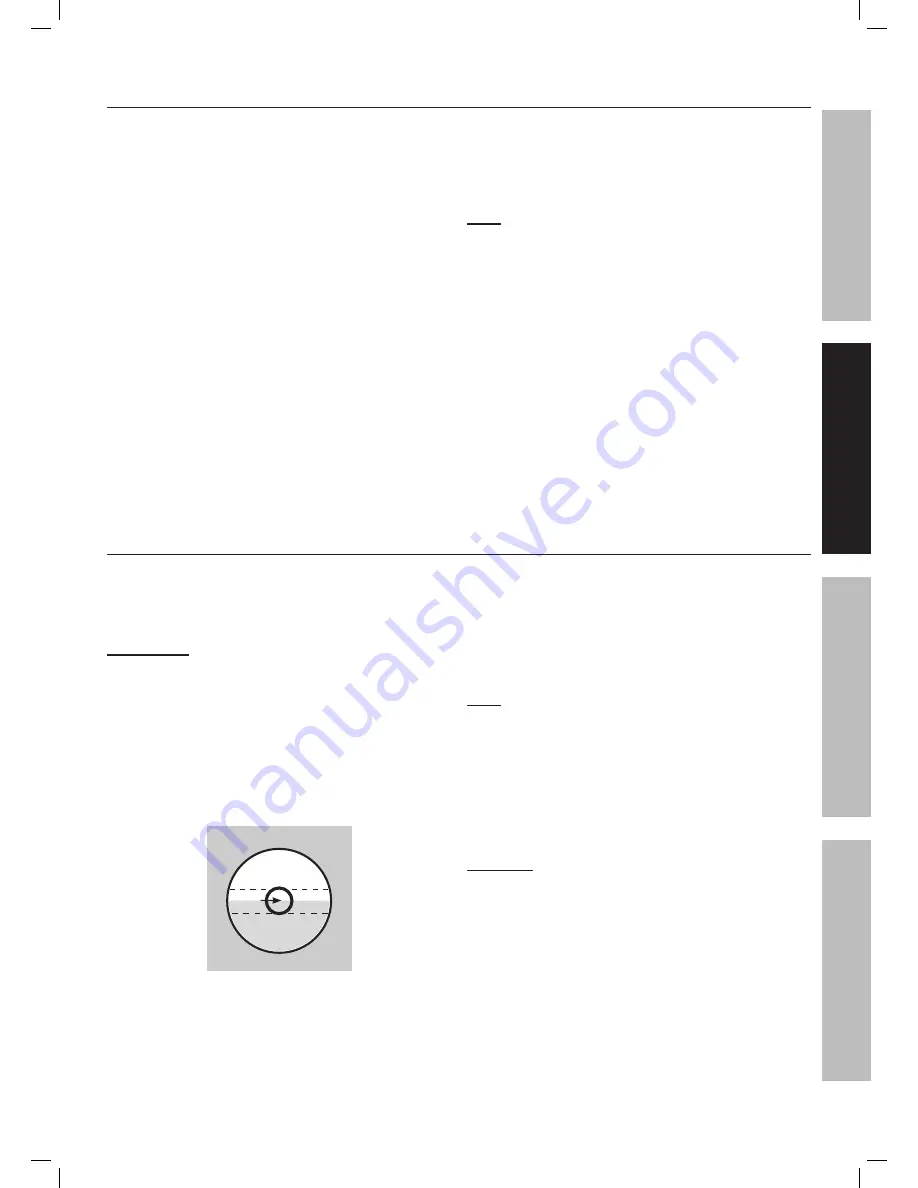

2. The oil level should be at the center of the “full” level

on the oil level sight glass, as shown in Figure B.

Add oil as needed to maintain this level.

Do not let the oil level go below the center dot

(LOW as shown above) and do not overfill

the oil so that it is above the center dot

(OVERFILL as shown above) on the sight glass.

OVERFILL

LOW

FULL

Figure B: Oil Sight Glass

3. To add oil:

a. Remove the Oil Plug.

b. Using a funnel to avoid spills, pour enough

oil into the Pump Crankcase to reach

the “full” level in the Oil Sight Glass.

c. Replace the Oil Plug.

Note:

SAE 30W, non-detergent,

Air Compressor Oil (sold separately) is

recommended for use with this compressor.

4. If uncertain which oil to use for this compressor,

call Harbor Freight Tools customer service

at 1-800-444-3353 for assistance.

5.

Change the compressor oil after the first

hour of use to remove any debris.

CAUTION! TO PREVENT INJURY FROM BURNS:

Do not add or change the oil while

the compressor is in operation.

Allow the compressor to cool before replacing oil.