SKU 90168

For technical questions, please call 1-800-444-3353.

Page 10

OPeRating instRuCtiOns

Read the entiRe iMPORtant

saFetY inFORMatiOn

section at the beginning of this

manual including all text under

subheadings therein before set

up or use of this product.

Close the Drain (9) completely.

1.

Turn the Tool Pressure Regulator

2.

(6)

counterclockwise

until it is fully

closed.

Pull the ring on the Safety Valve (3)

3.

to check that it operates properly.

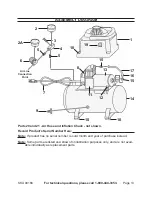

Attach the Air Hose (20) to the air

4.

outlet on the Regulator (6). Connect

the other end of the air hose to the air

inlet of the tool. Other components,

such as a connector and quick cou-

pler, will make operation more effi

-

cient, but are not required.

note:

If inflating tires or other objects,

connect the Air Hose (20) to the Infla

-

tion Chuck (21). Do not overinflate

any object.

Plug the Power Cord/Plug (7) into the

5.

nearest 120 volt, grounded, electrical

outlet.

Turn the Power Switch (19) to its

6.

autO

or

|

position.

Observe the Tank Pressure Gauge

7.

(2), and allow the air pressure in the

Tank (14) to build up to

70 Psi

.

Observe the Tool Pressure Gauge

8.

(2A), while turning the Tool Pressure

Regulator

clockwise

to increase pres-

sure up to the desired level.

WaRning! do not exceed the tool’s

maximum air pressure.

the air Compressor is now ready

9.

to use.

When finished using the Air

Compressor, turn the Power Switch

(19) to its

OFF

or

O

position. Then,

unplug the Air Compressor from its

electrical outlet.

Turn the Tool Pressure Regulator

10.

(6)

counterclockwise

until it is fully

closed.

Pull the ring on the Safety Valve (3)

11.

to relieve all remaining air pressure in

the Tank.

Activate the tool in a safe manner

12.

to release air pressure from the air

hose. Then, disconnect the air hose

from the tool, and store the compres-

sor in a safe, dry location.