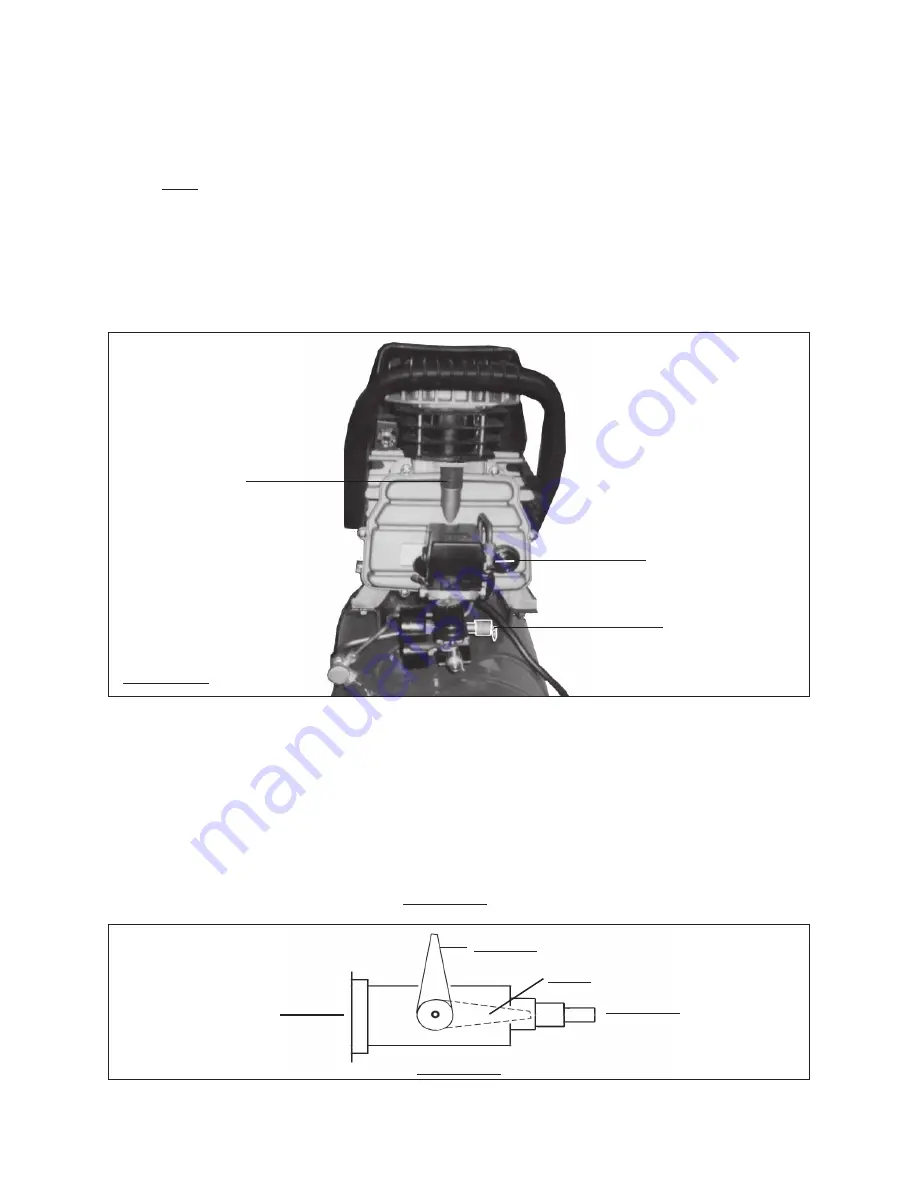

30-weight, non-detergent, compressor oil before each use. Running the Air

Compressor with no oil or low oil will cause damage to the equipment and

void the warranty. To check the level of oil, make sure the Air Compressor is

OFF. Then, observe the Oil Level Window (part #72). The level of oil should just

reach the horizontal line as shown on the Oil Level Window. If the level of oil is

below the horizontal line, remove the Oil Plug (part #78) and add new oil through

the Oil Plug hole.

Make sure not to overfill. The Air Compressor is designed to

hold approximately 25 fluid ounces of oil. Then screw in the Oil Plug, being

careful not to strip the threads.

(See Figure D.)

2.

Turn the Air Outlet Valve (part #69) to its CLOSED position. Then connect a high

pressure air hose (not included) equipped with a

quick connector to the Air Outlet

Valve. If using a water filter and oiler in series with the Air Outlet Valve of the Air

Compressor, connect the other end of the air hose to the water filter and oiler and

connect the water filter and oiler to the air tool being used. If not using a water

filter and oiler, squirt several drops of air tool oil into the air intake plug of the air

tool. Then, connect the other end of the air hose directly from the Air Outlet

Valve of the Air Compressor to the air tool.

(See Figure E, and Figure F, next page.)

AIR

OUTLET

VALVE

(#69)

CONNECT

AIR HOSE HERE.

CLOSED POSITION

OPEN POSITION

FIGURE E

SKU 90234

PAGE 10

REV 04/04

OIL LEVEL

WINDOW

(#72)

PRESSURE RELIEF

VALVE

(#67)

OIL PLUG

(#78)

FIGURE D