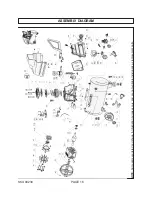

SKU 90234

PAGE 8

8.

When checking the oil level, make sure to unscrew (do not pull) the Oil

Plug (part #78) out.

9.

Drain the Air Compressor’s Tank (part #50) every day. Do not allow moisture

to build up inside the Tank. Do not open the Tank Drain Valve (part #59) so that

more than four threads are showing.

10.

Avoid injury. Never direct the Air Outlet Valve (part #69) at people or animals.

11.

Do not alter or remove the factory sealed Pressure Relief Valve (part #67).

12.

Dress properly. Do not wear loose clothing or jewelry as they can be caught in

moving parts. Wear restrictive hair covering to contain long hair.

13.

Do not overreach. Keep proper footing and balance at all times. Do not reach

over or across running machines.

15.

Industrial applications must follow OSHA requirements.

16.

Maintain this product with care. Keep this product clean for better and safer

performance.

17.

Maintenance: For your safety, service and maintenance should be performed

regularly by a qualified technician.

18.

Check for damaged parts. Before using this product, carefully check that it will

operate properly and perform its intended function. Check for damaged parts

and any other conditions that may affect the operation of this product. Replace

or repair damaged or worn parts immediately.

19.

Replacement parts and accessories: When servicing, use only identical re-

placement parts. Only use accessories intended for use with this product.

20.

Use the right tool or attachment for the job. Do not attempt to force a small

tool or attachment to do the work of a larger industrial tool or attachment.

There are certain applications for which this product was designed. It will do the

job better and more safely at the rate for which it was intended. Do not modify

this product, and do not use this product for a purpose for which it was not in-

tended.

21.

To extend the life of your air tools and equipment: It is recommended to

install a water filter and oiler (available from Harbor Freight Tools) in series with

the Air Outlet Valve (part #69) of the Air Compressor.

(See Figure C, next page.)