Page 7

SKU 92403

for technical questions, please call 1-800-444-3353

nOte

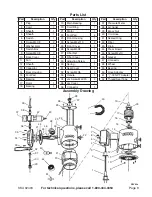

: Some parts are listed and shown for illustration purposes only and are not available

individually as replacement parts.

PleAse ReAd tHe fOllOwing CARefUlly

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS

MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR

MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR

SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALI-

FIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR

DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD

BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND NOT BY THE BUYER. THE

BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER

INSTALLATION OF REPLACEMENT PARTS THERETO.

Maintenance

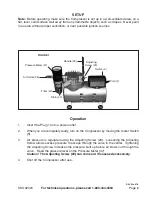

While operating the Compressor, make sure the Filter Cover (28) (see Assembly Draw-

ing on page 8), and the motor fan, are free of obstructions.

Periodically remove the Filter Cover (28) and make sure it is clean. It serves as a filter

for purifying the air the compressor takes in.

figURe 2

Drain (43)

The Filter (42) cup will fill with moisture from air that flows through the filter. After each

use, push the Drain (43) under the cup to drain off the moisture. See

figURe 2

.

note:

There are no user-serviceable parts in your Air Brush Compressor.

service should always be done by a qualified service technician.

note:

Never use any organic solvents such as thinner, alcohol, trichloroethylene,

etc. to clean the Filter Bowl. Only use dishwashing liquid.

1.

2.

3.