Page 5

SKU 92622

For technical questions, please call 1-800-444-3353

Assembly

The Air Hammer comes completely assembled, except for the air inlet fitting and handle.

Note: Use pipe thread seal or Teflon tape on all threaded connections.

Caution: The compressor must be off and all the air bled out before making any con-

nections.

Mount Handle

1.

Using Cap Screws (50), and the supplied Allen Wrench, mount the D-type Handle

(49) to the Hammer Case (43).

2.

Securely tighten all Cap Screws.

Air Connection

1.

Attach the Air Hose Fitting (56) into the Air Inlet (10) fitting. Securely tighten.

2.

Optionally, for easy connection or removal, attach an Air Quick Coupler (not supplied)

to a Union fitting (not supplied), if quick-coupling is desired.

3.

Attach the 1/2 inch air hose (not supplied) to the Air Hose Fitting (56), or Union fitting,

if used.

4.

Attach the other end of the air hose to the compressor (not supplied) regulator-filter

with oiler.

5.

Retighten all couplings and fittings.

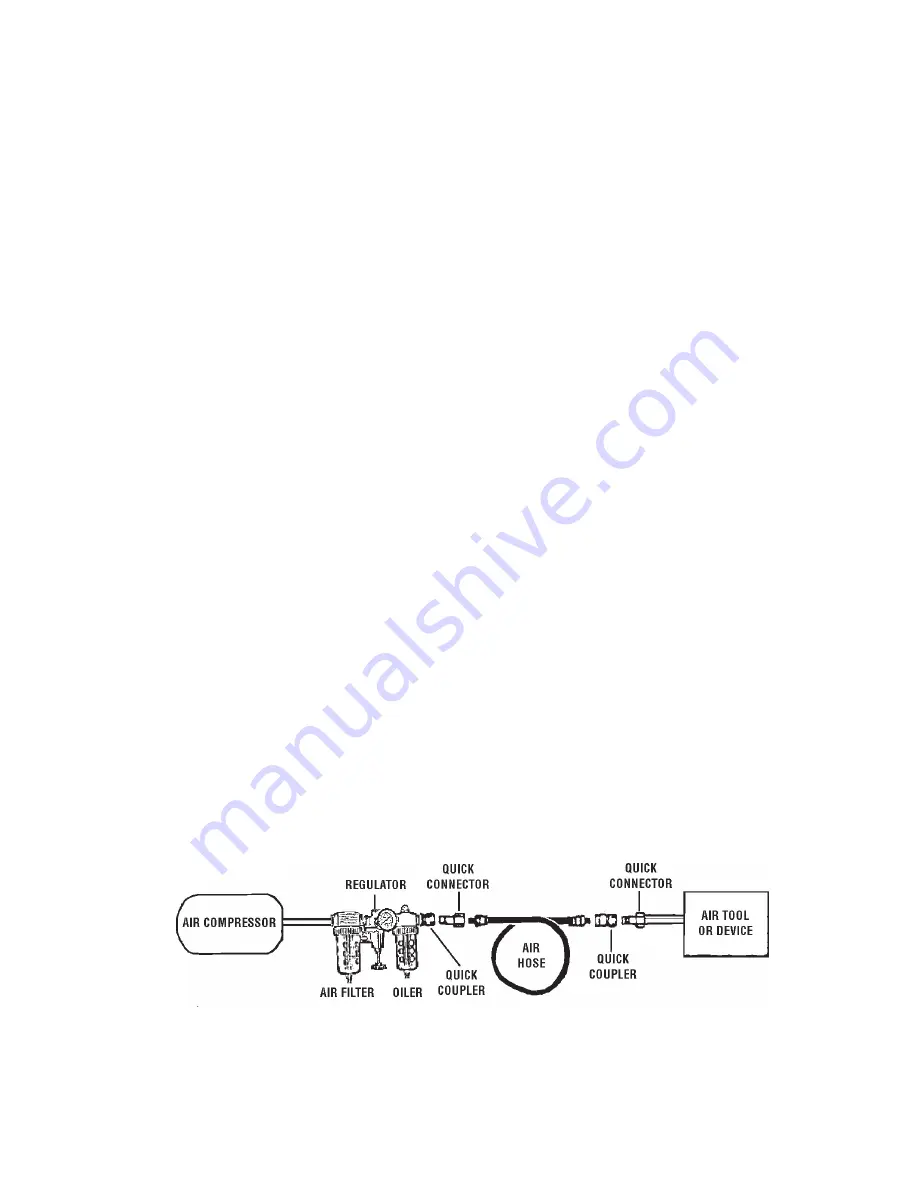

Oiler and Filter Connection

Dirt, water, and the lack of pneumatic tool oil are major causes for tool wear. It is recom-

mended to install an optional oiler-filter, as illustrated below for better performance.

Connect the air tool, air hoses, filter, and oiler to the Compressor Air Outlet as illustrated

below. The filter and oiler (not supplied) are recommended but not mandatory for operation.

A few drops of pneumatic tool oil must be added through the air line before each use if an

oiler is not used.