SKU 93351

For technical questions, please call 1-800-444-3353.

Page 10

UNPACKING

When unpacking, check to make sure all the parts shown on the

Parts List on page 17

are included. If any parts are missing or broken, please call Harbor Freight Tools at the

number shown on the cover of this manual as soon as possible.

ASSEMBLY INSTRUCTIONS

CAUTION!

Always make sure the ON/OFF Switch (86) of the Air

Compressor is in its

“OFF”

position and the unit is unplugged from its electrical

outlet prior to assembling the Compressor or making adjustments to the unit.

To Attach The Handle And Wheels:

1.

To attach the Handle (50A) to the Tank (50) of the Air Compressor, align the two

mounting holes in the Handle with the two mounting holes in the Tank. Secure

the Handle to the Tank, using the two Lock Knobs (50B).

(See Figure E.)

2.

To Attach the two Wheels (53) to the Tank (50) of the Air Compressor, insert a

Wheel (53) on each end of an Axle (53A). Secure the Wheels to the Axles, using

two Retaining Rings (54), then two Bolts (93).

(See Figure E.)

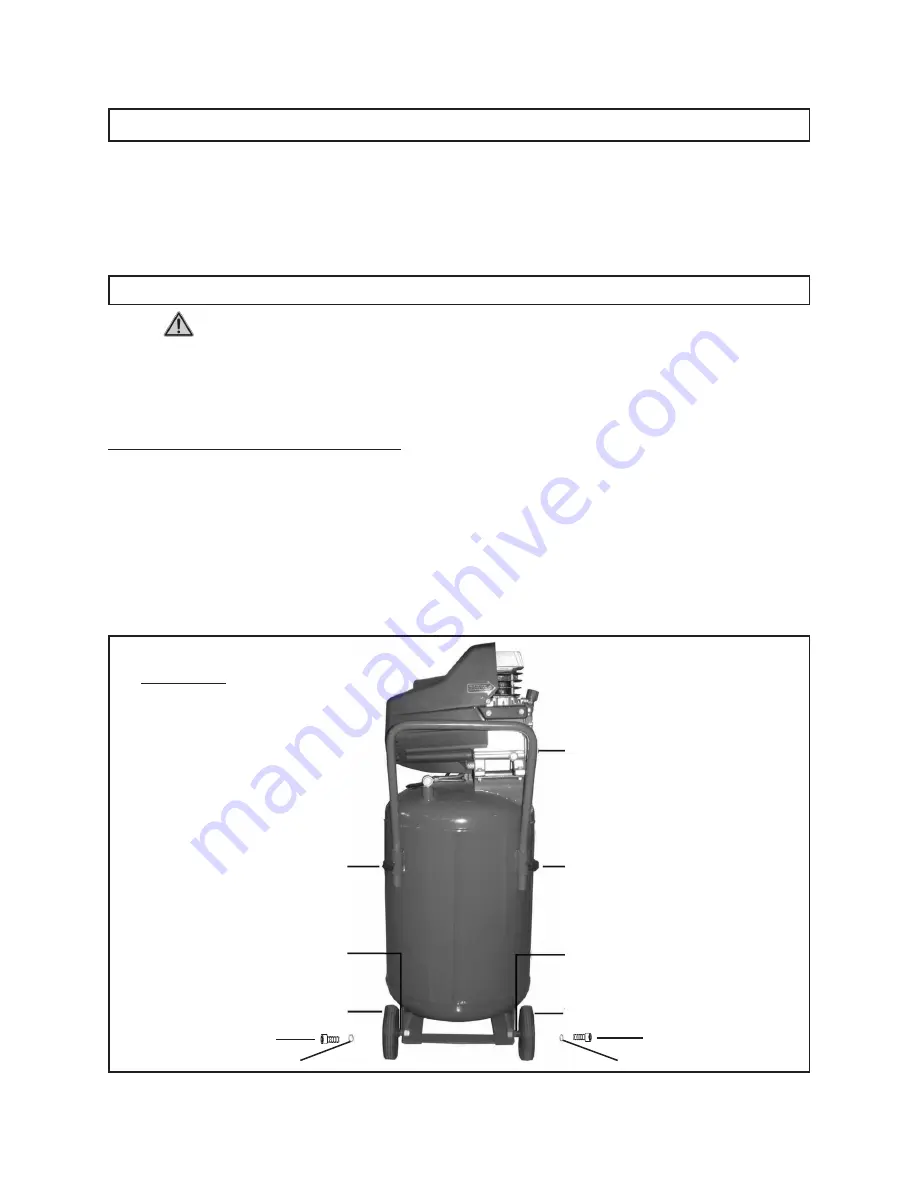

WHEEL (53)

WHEEL (53)

RETAINING RING (54)

RETAINING RING (54)

AXLE (53A)

AXLE (53A)

HANDLE (50A)

LOCK KNOB (50B)

LOCK KNOB (50B)

FIGURE E

REV 05/06

BOLT (93)

BOLT (93)