SKU 93351

For technical questions, please call 1-800-444-3353.

Page 5

SPECIFIC SAFETY RULES

WARNING! Your Warranty is voided if:

You do not put compressor oil in the Compressor’s crankcase prior to its

first use. Before each use, check the oil level. Never run the Compressor

with low or no compressor oil. Running the Compressor with low or no

oil will permanently damage the unit.

You use an extension cord with the Air Compressor. Connect the Air

Compressor’s Power Cord Plug

directly

to the nearest 120 volt, grounded,

electrical outlet. If necessary, attach a

longer air hose

to the Compressor.

You drop the Air Compressor. Do not lift the Air Compressor using its

Handle.

This Air Compressor may require a dedicated electrical circuit, as the amper-

age draw under full load combined with use of any other item may overload

your circuit.

Maintain labels and nameplates on the Air Compressor.

These carry important

information. If unreadable or missing, contact Harbor Freight Tools for a replace-

ment.

Always wear ANSI-approved safety impact eye goggles when assembling and

using the Air Compressor.

Maintain a safe working environment.

Keep the work area well lit. Make sure

there is adequate surrounding workspace. Always keep the work area free of ob-

structions, grease, oil, trash, and other debris.

DANGER!

This Air Compressor is NOT equipped and should not be used “as is”

to supply breathing quality air. For any application of air for human consumption,

you must fit the Air Compressor with suitable inline safety and alarm equipment

(not included). This additional equipment is necessary to properly filter and purify

the air to meet minimal specifications for Grade D breathing as described in Com-

pressed Gas Association Commodity Specification G 7.1-1966, OSHA 29 CFR

1910. 134, and/or Canadian Standards Associations (CSA). In the event the Air

Compressor is used for the purpose of breathing air application and proper inline

safety and alarm equipment is not simultaneously used, existing warranties are void,

and Harbor Freight Tools disclaims any liability whatsoever for any loss, personal

injury, or damage.

DANGER!

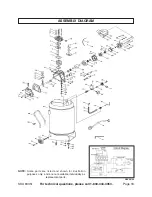

Never attempt to repair or modify the Tank (50). Welding, drilling, or

any other modification will weaken the Tank resulting in damage from rupture or

explosion. Always replace worn, cracked, or damaged Tanks.

1.

a.

b.

c.

2.

3.

4.

5.

6.

7.