SKU 93496

For technical questions please call 1-800-444-3353

Page 6

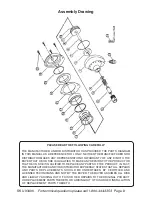

Operation

NOTE:

This tool is assembled when you receive it, and may be used immediately.

However, we recommend that you install a quick disconnect adapter (not included)

to the Air Inlet (23) before use.

WARNING:

Do not put a nail into the Air Palm Nailer until you are ready to work.

WARNING:

Do not point the Air Palm Nailer toward any person or animal. Severe

injury may result in case of accidental ejection of a nail.

1.

Attach the air supply hose (not included) to the tool.

2.

Grip the base of the tool in one hand. Note that there is a hand strap and

thumb strap on the Leather Cover (25) to facilitate holding the tool.

CAUTION: Whenever using this tool wear ANSI approved safety goggles.

3.

When ready to work, hold a nail by the shaft, and place the flat head into the

Hammer Tip (3). The nail will be held in place by the magnetic tip.

4.

Place the pointed end of the nail where desired on the workpiece. Keep your

free hand away from the tool and the nail.

5.

Press the tool straight down. This will trigger the tool and cause it to hammer

the nail. Continue pressing down until the nail is driven all the way in.

6.

You can adjust the force of the tool’s impact by adjusting the air pressure.

However, do not operate the tool at more than 125 psi.

CAUTION:

Disconnect the tool from air pressure supply when not in use, and

before making any adjustments.

7.

During operation, the Hammer Tip will hammer 1/4” up to 1,000 times per

minute. This tool is useful for driving nails in tight areas where a full sized air

nail gun may not reach.

8.

When the nail is hammered all the way down, the tool will stop operating. To

stop the tool, release the downward pressure on the Hammer Tip.

REV 11/06