Page 9

For technical questions, please call 1-888-866-5797.

Item 93657

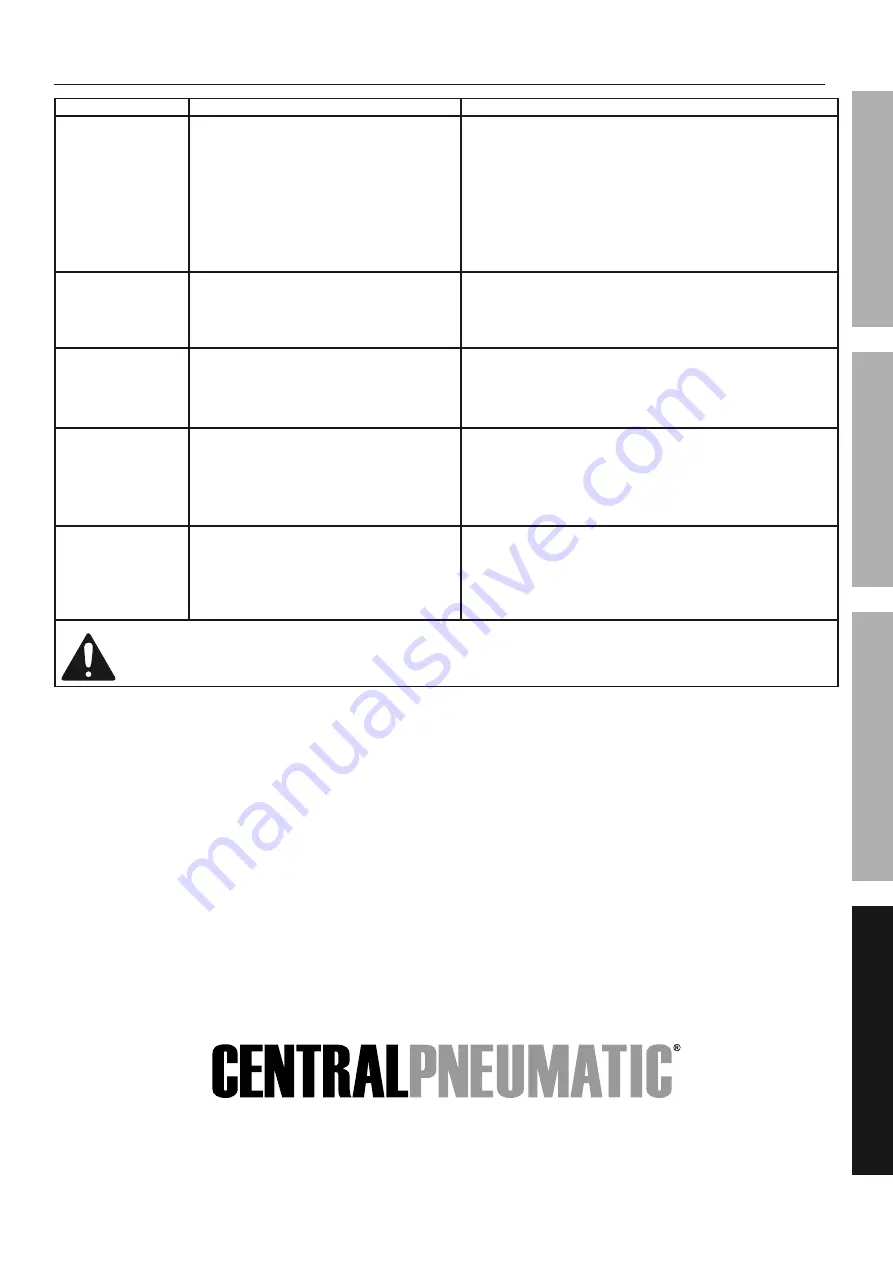

Troubleshooting

Problem

Possible Causes

Likely Solutions

The motor does

not work.

1. No electrical power.

2. Damaged power cord.

3. Electrical wiring within

the unit is defective.

4. Power switch is defective.

1. Plug the power cord into a working,

120VAC, grounded, electrical outlet.

2. Have a qualified service technician

replace the power cord.

3. Have a qualified service technician

replace electric wiring.

4. Have a qualified service technician

replace power switch.

The motor runs,

but it makes

irregular noises or

a knocking noise.

1. Bearing is loose or damaged.

2. Screws in the connection

rod are loose.

1. Have a qualified service technician

replace the bearing.

2. Tighten the screws, or replace them if necessary.

Not enough

pressure when

painting or

spraying.

1. Loose air connection(s).

2. Air hose is damaged.

3. Screws on cylinder cover are loose.

1. Check all air connections, and

tighten them if necessary

2. Replace air hose.

3. Tighten screws.

Poor spray pattern. 1. Loose air connections(s).

2. The paint is too thick.

3. The air brush nozzle is

plugged or dirty.

1. Check all air connections, and

tighten them if necessary.

2. Add paint thinner and mix thoroughly.

3. Clean or change the nozzle.

Motor runs

properly, but no air

pressure or lack

of air delivery.

1. Valve plate is loose or out of place.

2. Retainer ring is damaged after

excessive use at high pressure.

1. Open the front cover and make sure

the valve plate is in the proper position.

Tighten the screws if necessary.

2. Have a qualified service technician

replace the retainer ring.

Follow all safety precautions whenever diagnosing or servicing the compressor.

Disconnect power supply before service.

SAFETY

OPERA

TION

MAINTENANCE

SETUP