Page 10

For technical questions, please call 1-888-866-5797.

Item 93755

SA

FE

TY

OP

ERA

TI

O

N

MAINT

ENANC

E

SE

TUP

Assembly

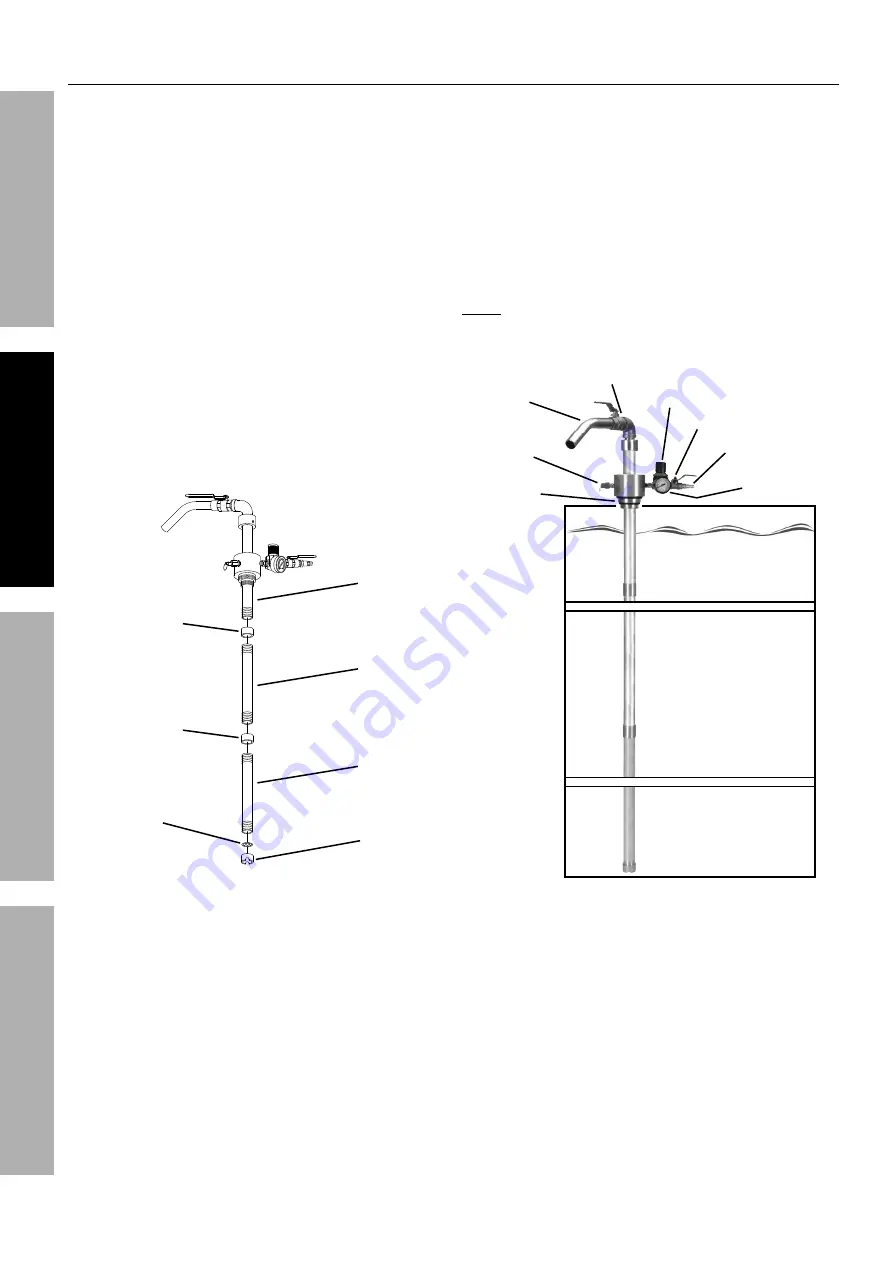

1. Wrap 4" of pipe sealer tape (not included) around

the male threads located on the lower section of

Suction Tube A (5). Then firmly screw a Suction

Tube Coupler (7) onto the Suction Tube.

2. Wrap 4" of pipe sealer tape around the male

threads on both ends of Suction Tube B (6). Then

firmly screw one end of Suction Tube B into the

Suction Tube Coupler attached to Suction Tube A.

3. Firmly screw the remaining Suction Tube Coupler

onto the lower section of Suction Tube B.

4. Wrap 4" of pipe sealer tape around the

male threads on both ends of the remaining

Suction Tube C (8). Then firmly screw one

end of Suction Tube C into the Suction Tube

Coupler attached to Suction Tube B.

5. Insert the Oil Filter (9) into the Inlet Plug (10).

Then, firmly screw the Inlet Plug onto the

lower section of Suction Tube C.

Inlet Plug

(10)

Oil Filter

(9)

Suction Tube

Coupler (7)

Suction

Tube A

(5)

Suction Tube

Coupler (7)

Suction

Tube B

(6)

Suction

Tube C

(8)

Figure C: Suction Tube Setup

6. Unscrew and remove the large bung from

the barrel of liquid to be extracted.

7. Insert the lower section of the Drum Extractor

through the bung of the barrel. Then

firmly screw the Drum Extractor into

the female threads of the bung.

8. To adjust the length of the tube in the

barrel, grasp the regulator assembly

and twist it up or down on the pipe.

Note:

The male threads of the Drum Extractor

are designed to fit a 1-1/2" or 2" diameter

bung. Refer to Figure D: Barrel Setup.

Barrel

(not included)

Outlet

Tube

Air Inlet Ball Valve

Regulator

Pressure

Gauge

Air Quick Coupler

Outlet Ball Valve

Pressure

Release

Valve

1-1/2"

~

2"

Diameter

Threads

Figure D: Barrel Setup