Page 14

For technical questions, please call 1-888-866-5797.

Item 93755

SA

FE

TY

OP

ERA

TI

O

N

MAINT

ENANC

E

SE

TUP

Parts List and Diagram

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY DIAGRAM

IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR DISTRIBUTOR

MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS

QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS QUALIFIED TO REPLACE

ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR EXPRESSLY

STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND

LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY

ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS

THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

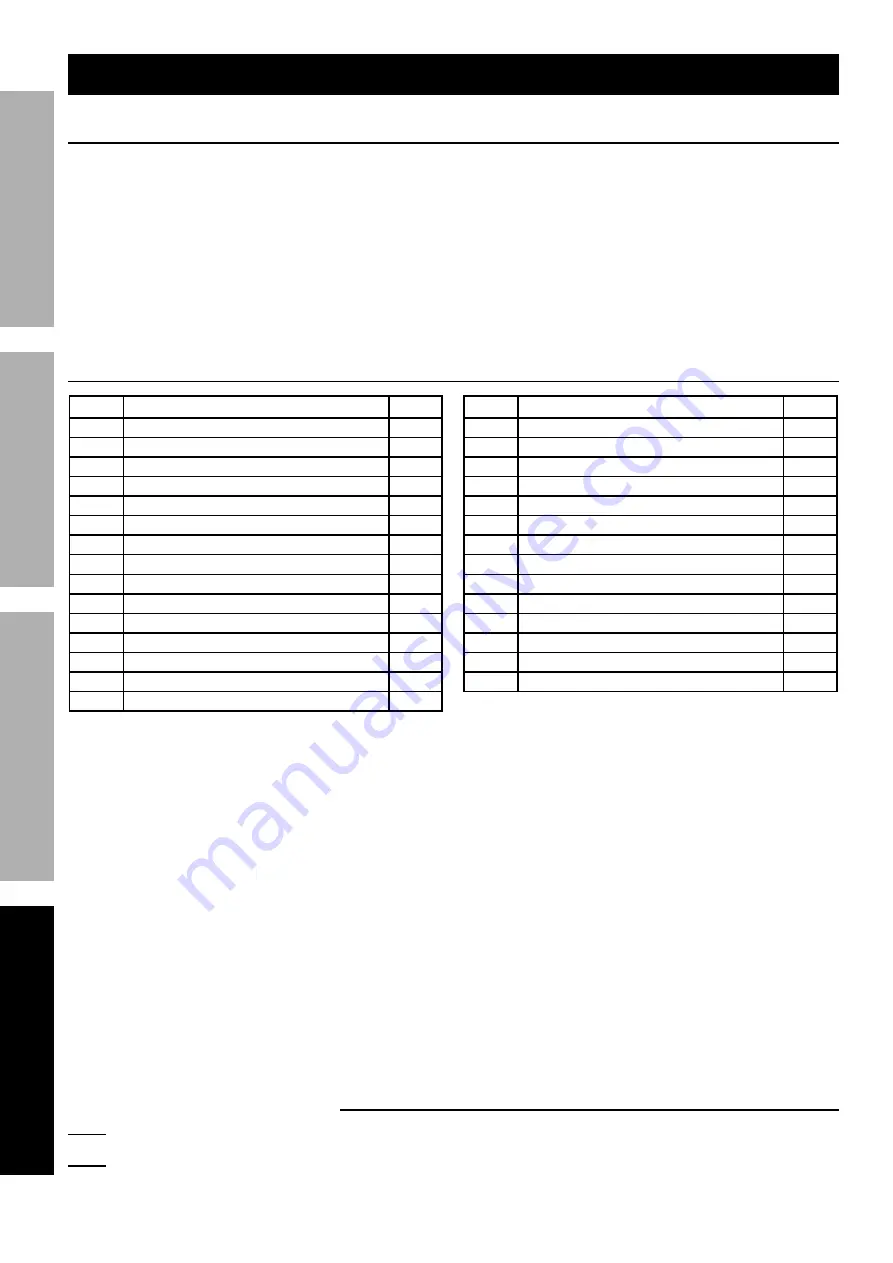

Parts List

Record Product's Serial Number Here:

Note:

If product has no serial number, record month and year of purchase instead.

Note:

Some parts are listed and shown for illustration purposes only, and are not available

individually as replacement parts. Specify UPC 193175451507 when ordering parts.

Part

Description

Qty

1

Pressure Gauge

1

2

Air Quick Coupler

1

3

Air Inlet Ball Valve

1

4

Air Pressure Regulator

1

5

Suction Tube A

1

6

Suction Tube B

1

7

Suction Tube Coupler

2

8

Suction Tube C

1

9

Oil Filter

1

10

Inlet Plug

1

11

O-Ring

1

12

O-Ring

1

13

Housing

1

14

Valve Body

1

15

Control Bolt

1

Part

Description

Qty

16

Lock Nut

1

17

Valve Core

1

18

Spring

1

19

Pull Ring

1

20

Valve Cover

1

21

Outlet Tube

1

22

Outlet Ball Valve

1

23

Elbow

1

24

Swivel Coupler

1

25

O-Ring

1

26

O-Ring

2

27

Screw Cap

1

28

Coupler

1

29

Valve Core

1