SKU 93786

For technical questions please call 1-800-444-3353

Page 5

Air Compressor Pump Safety Precautions

1.

Use proper size motor and motor pulley.

This air compressor Pump must

be installed with a 5 HP electric motor and pulley (both not supplied) which

can turn the Air Compressor Belt Wheel (36) at approximately 1050 rpm, but

not more than 1200 rpm.

2.

Install motor, pully belt and pully belt cover securely.

Be sure to use the

proper size bolts to install your motor (not included). The belt and belt cover

(not included) must be strong enough to prevent breaking and possible injury.

3.

Be sure all equipment is rated to the appropriate capacity of this pump.

Make sure that the lowest rated piece of equipment you are using can handle

the maximum pressure of the Air Compressor Pump (see Specifications).

4.

Avoid explosions and fire.

Never place flammable objects near the compressor.

Never spray water or any flammable liquids towards the compressor.

5.

Avoid bodily injury.

Never direct the air outlet at any person or animal.

6.

Use Safety Guard for Pulleys.

The Air Compressor Belt Wheel (36), V-belt

(not supplied), and motor pulley (not supplied) must be covered by a safety

guard (not supplied) covering all moving elements before operation.

7.

Avoid burns.

The Cylinder (15), Cylinder Head (26) Air Hose (24) and Air

Outlet (25) become very hot during operation. Do not touch.

8.

Industrial Applications.

If used in an industrial applications, you must follow

OSHA requirements.

9.

Properly fill Air Compressor Pump oil reservoir before operating.

Fill

the oil reservoir with a premium quality, 30-weight, non-detergent oil before

operating.

Check oil level through the Oil Level Window before each use.

Running the Air Compressor Pump with little or no oil will cause damage to

the pump and void the warranty.

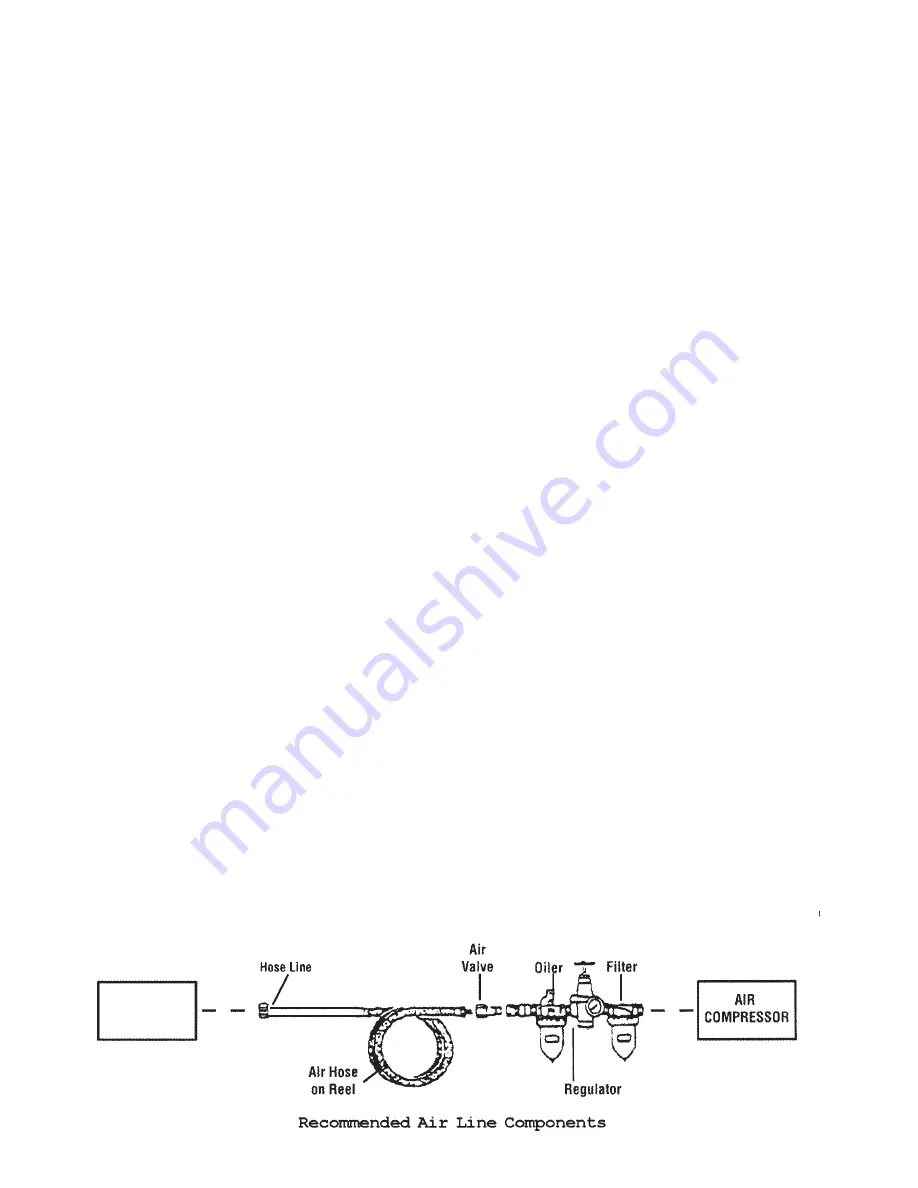

Recommended Compressed Air System Components

We recommend that you use both a filter and an in-line oiler in your air supply system

as illustrated in the diagram below. These components are not included with this tool,

but are available from Harbor Freight Tools.

Air Tool