SKU 94734

For technical questions, please call 1-800-444-3353.

Page 8

REV 07b

OPERATION

CAuTION! Prior to use, inspect the compressor for any damaged parts or unsafe con-

ditions. Make any necessary repairs before using again.

Turning Compressor On

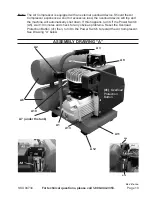

1. Verify Tank Drain Valve (A-7) is closed.

2.

Verify oil level is correct.

3. Verify that the Safety Valve (A-4) is operational.

4. Turn the Air Flow Valve (A-8) to the OFF position.

5. Plug the power cord into an electrical grounded 115 Volt AC electrical receptacle.

6. Rotate the Power Switch (A-5) to the Vertical position to turn the air compressor on.

Rotate that same switch to the horizontal position to turn it off. See page 10.

Note:

Allow the pressure to build up to at least 80 PSI before using air.

Note:

Motor will not start if tank pressure is already between 80-115 PSI. Pressure

MuST

be below 80 PSI for motor to restart and build up pressure to the 115 PSI cut off

pressure.

7. Open the Air Flow Valve (A-8) and check for air leaks.

The operation of the compressor is automatic, as controlled by the internal pressure

switch. When the pressure drops below its operating range the compressor turns on.

When the pressure is above 115 PSI, the compressor shuts off.

Warning; The compressor will become very hot during operation. do not touch the

cylinder area of the compressor, or allow flammable materials to come in contact with

the cylinder area.

Adjusting Pressure gauge and Pressure Adjustment Screw

Caution: The Pressure Switch is adjustable but changes to the pressure levels are not

recommended; any change to the automatic ON/OFF pressure levels will cause addi-

tional stress on the motor which may shorten motor life.

Adjusting Air Output

1. When the Air Flow Valve (A-8) is to the right or left, the valve is closed. When it is in

the middle, it is open.

2. Turn the Air Flow Valve to the appropriate pressure.