Page 11

SKU 95370

for technical questions, please call 1-800-444-3353.

INSPECTION, MAINTENANCE, ANd CLEANING

wARNING! Make sure the Pressure Switch (A29) of the tool is in its “Off” posi-

tion and that the tool is unplugged from its electrical outlet, and all air released from

the Tank before performing any inspection, maintenance, or cleaning procedures.

bEfORE EACH uSE,

inspect the general condition of the tool. Check for loose

screws, misalignment or binding of moving parts, cracked or broken parts, dam-

aged electrical wiring, and any other condition that may affect its safe operation. If

abnormal noise or vibration occurs, have the problem corrected before further use.

do not use damaged equipment.

Purge Tank daily of all air and condensation to prevent corrosion.

Store the Air Compressor in a clean and dry location.

Check all air fittings for leaks before using.

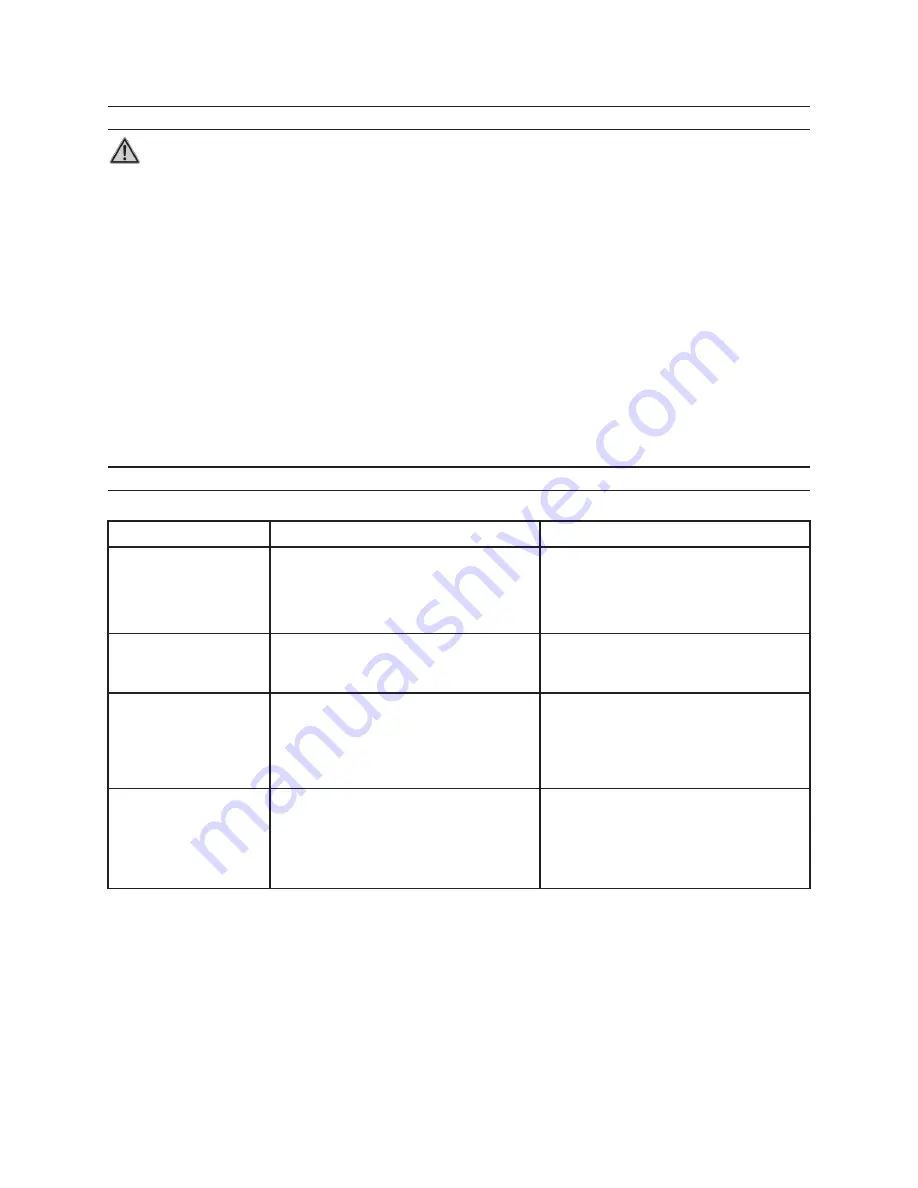

TROubLESHOOTING

Problem

Possible Causes

Probable Solutions

Air Compressor will

not start

Pressure Switch (A29) in Off

position.

No power at outlet.

Line cord not plugged in.

1�

2�

3�

Push Pressure Switch to Auto

position.

Check power at outlet.

Plug line cord into electrical outlet.

1�

2�

3�

Air Compressor stops

during long period of

use.

Thermal Protection has

automatically shut the motor off.

1�

Allow the motor and compressor to

cool down, then press in the motor

reset button.

1�

Tank air pressure

does not reach

115 PSI and Air

Compressor runs

continuously.

Air Leaking at Tank Drain Valve

(A13).

Air hose has leak.

1�

2�

Tighten Tank Drain Valve.

Tighten or repair air hose.

1�

2�

Air tool not operating

at proper speed.

Air output pressure low.

Air hose has leak.

1�

2�

Adjust Pressure Adjustment knob

so Air Output Pressure Gauge

reads the proper air pressure for

the air tool being used.

Tighten or repair air hose.

1�

2�

1.

2.

3.

4.