SKU 95386

For technical questions, please call 1-800-444-3353.

Page 15

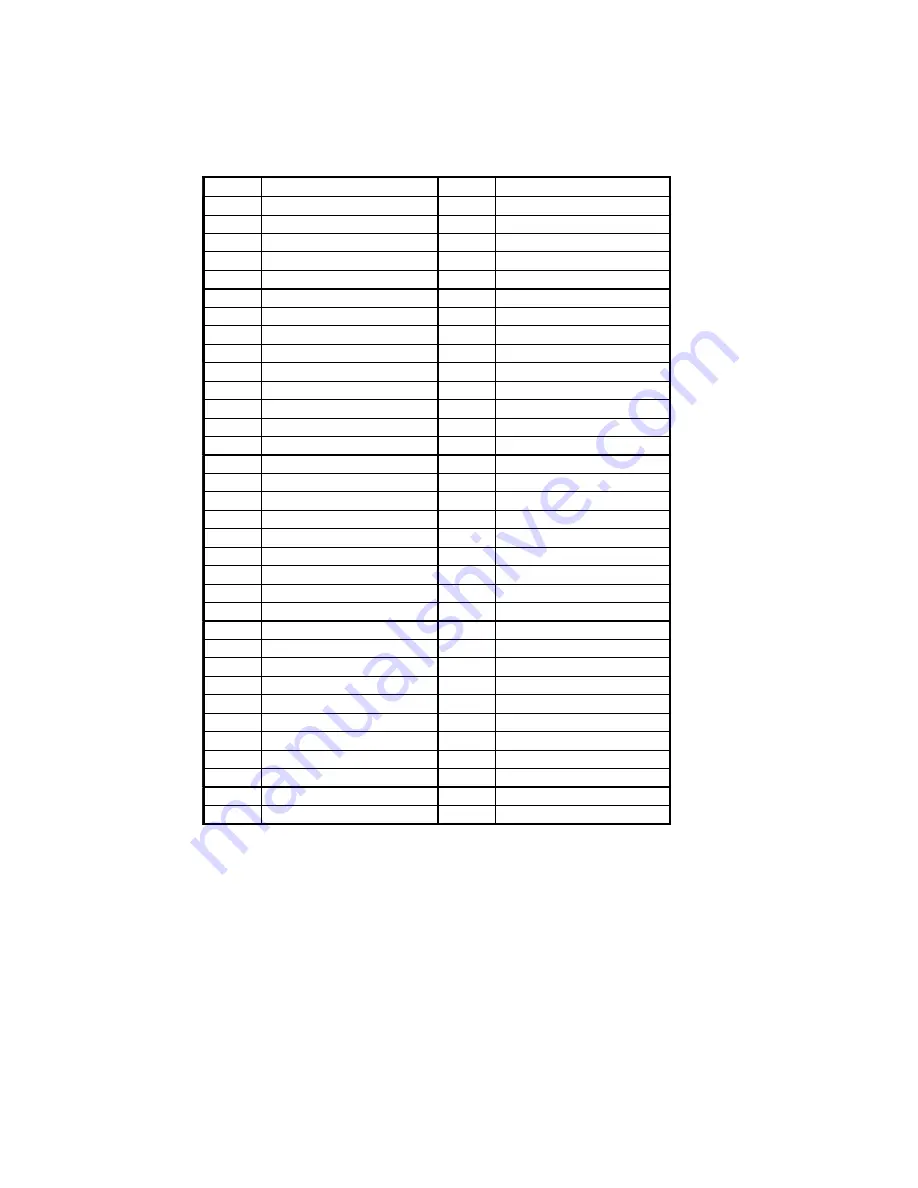

PARTS LIST

Part #

Description

Part #

Description

1 Air

tank

35

Handle

2

M8 nut

36

Cylinder gasket

3

Spring washer 8

37

Connecting rod

4 Flat

washer

38

Piston

5

Wheel assembly

39

Oil clean ring

6

Wheel shaft screw

40

Seal ring

7 O-sealed

washer

41

Cylinder

8

Tank cap

42

Valve plate gasket

9

Sealed washer

43

Right-angle connector

10 Exhaust

pipe

assembly

44 Screw

M8x105

11

Spring washer

45

Air filter

12 Protection

Cover

46 Cylinder

cover

13 Fan

47 Cylinder

gasket

14

Black motor cover

48

Valve plate assembly

15 Wave

washer

49 Limit

pin

16 Bearing

6202-RZ

50 Air

intake

valve

17 Screw

M5x105

51 Piston

pin

18 Stator

52 Circlip

19 Reset

button

53 Lock

nut

20

Rotator assembly

54

Tank pressure gauge

21 Capacitor

55 Pressure

switch

22

Serrated washer 8

56

Safety valve

23 Screw

M5x10

57 Connector

24 Bearing

6204-RZ

58 Regulator

assembly

25

Oil Seal B20x40

59

Quick coupling

26 Screw

M12x12

60 Output

Pressure

Gauge

27 Crankcase

61 Screw

M8x30

28 Crank

62 Unload

pipe

29 Screw

M12x12

63 Outlet

valve

30

Crankcase cover gasket 64

Cord and plug

31 Oil

plug

65 Drain

valve

32 Crankcase

cover

66 Rubber

foot

33 Oil

sight

gauge

67 Screw

M8x25

34 Screw

M5x12