SKU 95498

For technical questions, please call 1-800-444-3353.

Page 13

Problem

Possible Cause

Possible Solution

Oil discharge in air.

Too much oil in

1.

crankcase.

Compressor overheated.

2.

Restricted oil breather

3.

cap.

Drain crankcase and refill to proper level on

1.

sight glass.

Reduce air pressure regulation.

2.

Clean or replace oil breather cap.

3.

Pressure switch will not

turn off Compressor.

Defective pressure switch.

Immediately unplug Compressor from its

electrical outlet. Do not operate Compressor

until a qualified service technician can replace

pressure switch.

PLEASE REAd THE FOLLOWING CAREFuLLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR

DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT

HE OR SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/

OR DISTRIBUTOR ExPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD

BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE

BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER

INSTALLATION OF REPLACEMENT PARTS THERETO.

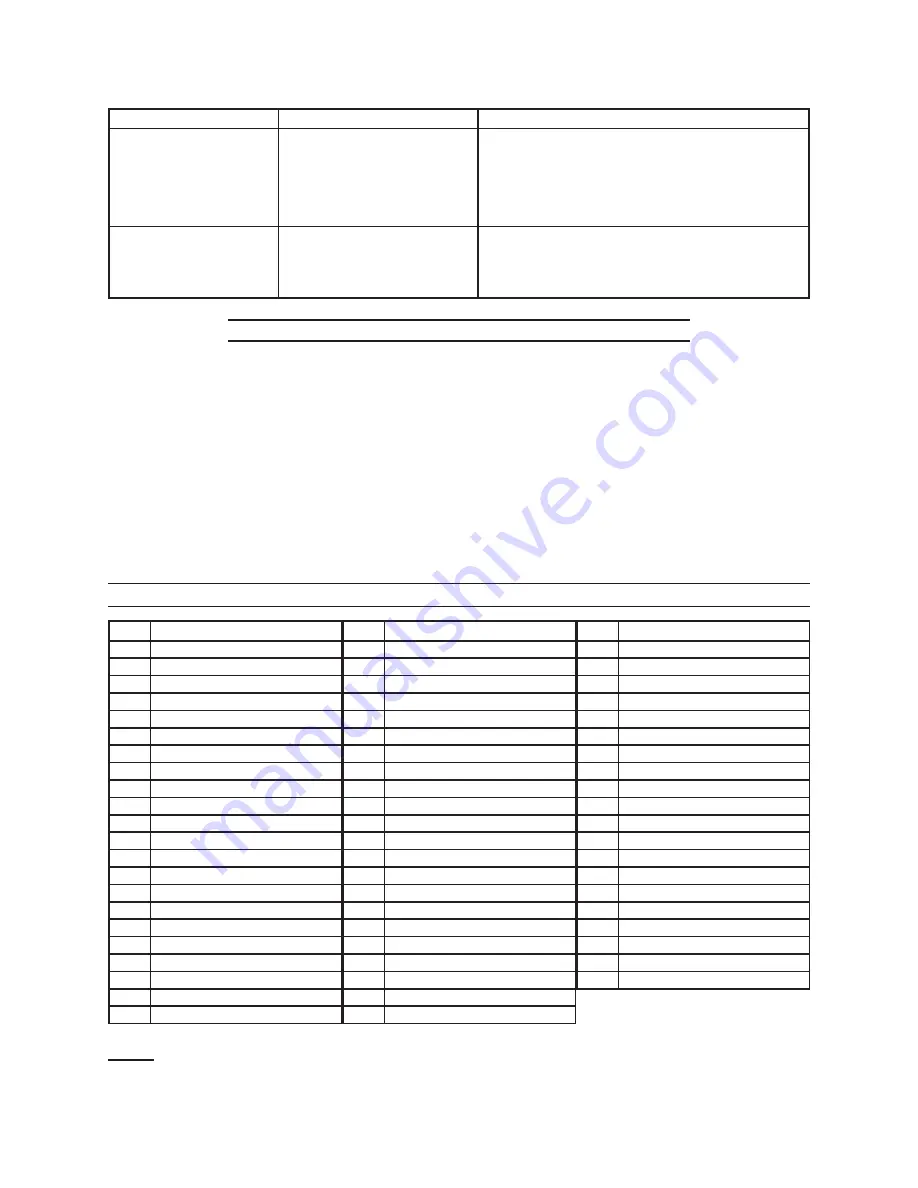

PARTS LIST

Part

description

1

Plastic Housing

2

Spring Washer

3

Washer

4

Screw (M5 x 14)

5

Fan

6

Screw (5 x 115)

7

Rear Cap

8

Washer

9

Bearing (6202)

10 Stator

11 Rotor

13 Running Capacitor

14 Bearing (6204)

15 Oil Seal

16 Nut (M8)

17 Crankcase

18 Crankshaft

19 Screw (M8 x 16 – Left hand)

20 Gasket

21 Crankcase Cover

22 Oil Sight Glass

23 Drain Plug

Part

description

24 Pan Head Screw

25 Oil Breather Cap

26 Spring Washer (#8)

27 Washer (#8)

28 Screw (M8 x 20)

29 Connecting Rod

30 Piston

31 Spring Washer

32 Piston Pin

33 Cylinder Gasket

34 Cylinder

35 Spring Washer (#6)

36 Washer (#6)

37 Screw (M6 x 40)

38 Gasket

39 Sealer Ring

40 Valve Gasket

41 Valve Plate Assy.

42 Air Intake Valve

43 Limit Pin

44 Cylinder Gasket

45 Air Filter

Part

description

46 Cylinder Head

47 Elbow Exhaust

48 Exhaust Pipe

49 Check Valve

50 Unload Pipe

51 Air Tank

52 Tank Drain Valve

53 Rubber Foot

54 Screw (M6 x 20)/Nut (M6)

55 Power Cord

56 Rubber Gasket

61 Rubber Grip

62 Safety Release Valve

63 Tank Pressure Gauge

64 Pressure Switch

65 Connector

66 Tool Pressure Gauge

67 Regulator

68 Air Outlet Valve

79 Frame Assy.

Note:

Some parts are listed and shown for illustration purposes only, and are not avail-

able individually as replacement parts.

REV 08k