OPERATING INSTRUCTIONS

NOTE: For additional references to the parts mentioned in the following pages, refer to

the Assembly Diagram on page 10.

To Check The Oil Level:

1.

The Oil Window (part #25) is used to determine if oil is needed. To check the oil,

observe the Oil Window. The oil should appear at the midway point (horizon-

tally) in the circle of the Oil Window. (See Figure D.)

Note: The optimal capacity of the oil tank is 28.73 ounces.

8.

Attach the Air Compressor Tank’s Inlet Hose (not included) to the 1/2” by 14-TPI

Exhaust Elbow (part #3). NOTE: Make sure to wrap the male threads of Tank’s

Inlet Hose

Connector with pipe seal tape (not included). Then, screw the Con-

nector firmly into the Exhaust Elbow. (See Figure D.)

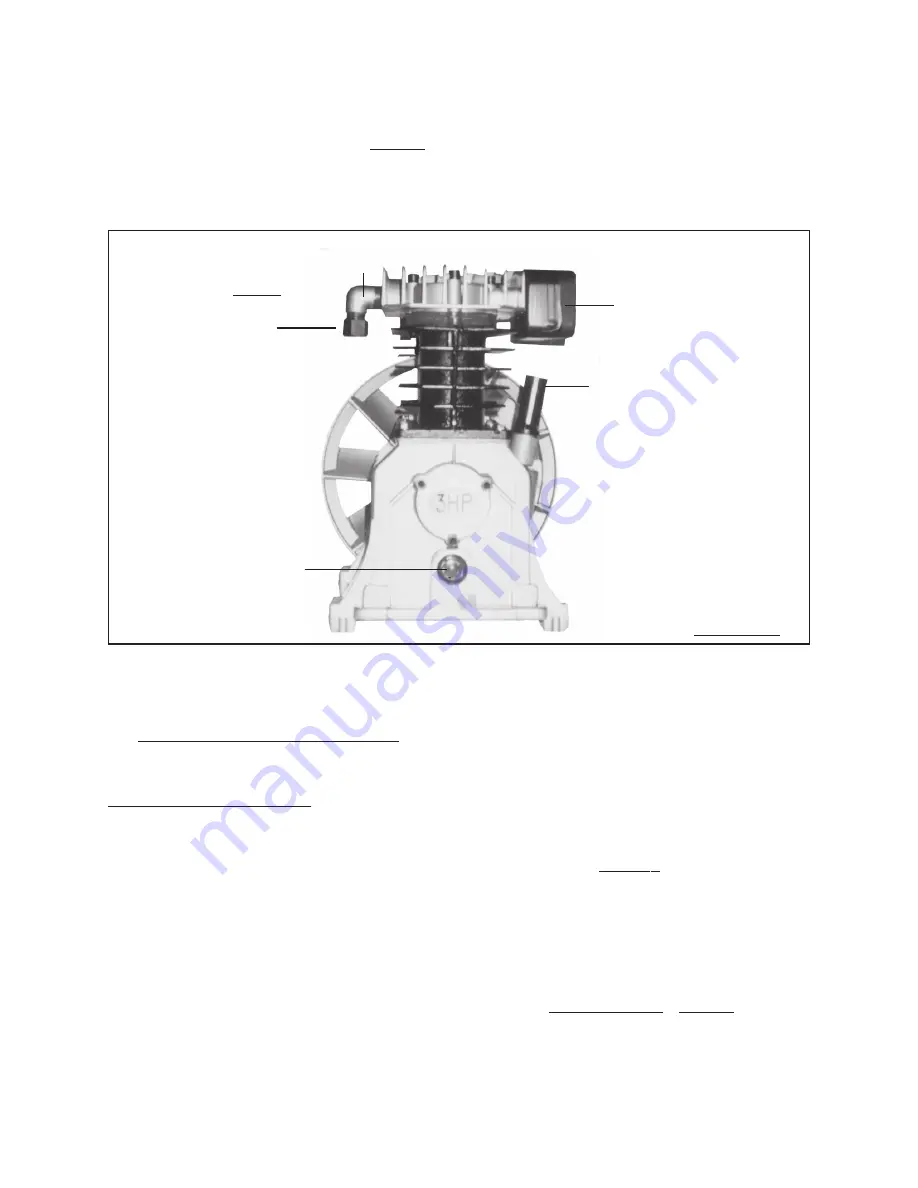

EXHAUST ELBOW

(#3)

AIR FILTER

(#4)

OIL FILL PLUG

(#20)

OIL WINDOW

(#25)

FIGURE D

ATTACH

AIR TANK INLET HOSE

(NOT INCLUDED)

HERE.

2.

If the oil level is below the midway point in the Oil Window (part #25) then it is

necessary to add a

premium quality, 30-weight, non-detergent oil until the level of

oil reaches the midway point in the Oil Window. Do not overfill. NOTE: Make

sure to unscrew the Oil Fill Plug and remove it from its Oil Fill Hole. Add the

new oil. Then screw the Oil Fill Plug back into the Oil Fill Hole, being careful not

to strip the threads. (See Figure D.)

SKU 09592

PAGE 7

REV 02/04