Page

SKU 96496

For technical questions, please call 1-800-444-3353.

SPECIFICAtIONS

Electrical Requirements

120 V~ / 60 Hz / 13 Amps (Running)

4 HP Motor (Peak) / 100 Watts (Running) / 13000 Motor RPM

Motor Thermal Protection Shut-Off: 266 Degrees Fahrenheit

Thermal Protection Reset: Present (1 Amp Circuit Breaker Used)

Power Cord: 16 AWG x 3C / 6’ Long

Power Plug: 3-Prong / Grounded

Compressor Type

Oilless for Maintenance Free Operation

Maximum Air Pressure

1 PSi

Air Delivery

4.0 SCFM @ 90 PSi / 6.0 SCFM @ 40 PSi

Air Tank Capacity

26 Gallons

Female Air Outlet Size

1/4”-1 NPT

Automatic

Turn-On/Shut-Off

Pressure

12 PSi Automatic Turn-On

1 PSi Automatic Shut-Off (+ or - PSi)

Additional Features

Two 7-3/4” Diameter x 1-3/4” Tires

Built-in Tool Storage Compartment

Overall Dimensions

43-7/” H x 17-3/4” W x 21-1/4” L (Up to Handle)

Net Weight

6 Pounds

uNPACKING

When unpacking, check to make sure that the item is intact and undamaged. if

any parts are missing or broken, please call Harbor Freight Tools at the number shown

on the cover of this manual as soon as possible.

SEt uP INStRuCtIONS

Read the ENtIRE IMPORtANt SAFEtY INFORMAtION section at the

beginning of this manual including all text under subheadings therein

before set up or use of this product.

Risk of accidental starting; resulting in serious personal

injury. turn the Power Switch of the tool to its “OFF”

position and unplug the tool from its electrical outlet before

assembling or making any adjustments to the tool.

Note:

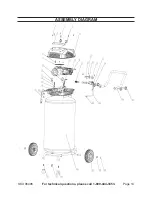

For additional information regarding the parts listed in the following pages, refer

to the Assembly Diagram near the end of this manual.

Assembly

CAutION!

Always make sure the Air Compressor’s Power Switch (2) is in its

“OFF”

position prior to performing any service, maintenance, or cleaning of the

Compressor.

1.

WARNING

WARNING