Page 11

SKU 97080

For technical questions, please call 1-800-444-3353.

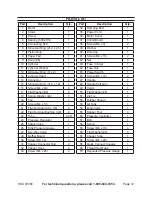

Problem

Possible Cause

Possible Solution

Compressor will not start.

Blown fuse or circuit breaker

1.

tripped.

Loose electrical

2.

connections.

Bad Capacitors.

3.

Replace fuse.

1.

Make sure Compressor is plugged

2.

into a working, 120 volt, grounded,

electrical outlet.

Replace Capacitors.

3.

Low pressure.

Defective check valve.

1.

Air leak in safety valve.

2.

Defective Valve Plate.

3.

Drain Valve not fully closed.

4.

Have a qualified service technician

1.

replace check valve.

Check valve by pulling on ring. If

2.

condition persists, have a qualified

service technician replace valve.

Replace Valve Plate.

3.

Close Drain Valve.

4.

Safety valve releasing.

Defective pressure switch.

1.

Defective Safety Valve

2.

.

Have a qualified service technician

1.

replace pressure switch.

Replace Safety Valve.

2.

Pressure switch will not turn

off Compressor.

Defective pressure switch.

Immediately unplug Compressor from

its electrical outlet. Do not operate

Compressor until a qualified service

technician can replace pressure

switch.

before each use,

2.

inspect the general condition of the Air Compressor. Check for

loose screws, misalignment or binding of moving parts, cracked or broken parts,

damaged electrical wiring, loose air fittings, and any other condition that may affect

the safe operation of the Compressor. If abnormal noise or vibration occurs, have

the problem corrected before further use.

Do not use damaged equipment.

Daily, purge the Air Tank (53) of all air and moisture to prevent corrosion. To do so,

3.

slowly and carefully unscrew (no more than four threads) the Tank Drain Valve (54)

until the compressed air and condensation begins to be released from the Tanks.

Allow sufficient time for all of the air and condensation to escape from the Tanks.

Then, firmly re-tighten the Drain Valve.

CAUTION! All maintenance, service, or repairs not mentioned in this manual must

4.

only be performed by a qualified service technician.

To replace the Fuse (43), unscrew the fuse and replace with a 250V, 3A fuse.

5.

tROubLEShOOtING

INSPECtION, MAINtENANCE, ANd CLEANING

WARNING!

1.

Make sure the ON/OFF Power Switch (45) of the Air Compressor

is in its “STOP” position, the unit is unplugged from its electrical outlet, and air is

drained from the Tank (53) before performing any inspection, maintenance, or

cleaning procedures or leaving it unattended.