SKU 98635

For technical questions, please call 1-800-444-3353.

Page 7

which satisfies OSHA requirements

and complies with the applicable

standards of Underwriters Labora-

tories, Inc., the Canadian Standard

Association, and the National Electri-

cal Code.

(See Outlets for 2-Prong

Plug.)

Double insulated tools may be used

2.

in either of the 120 volt outlets shown

in the preceding illustration.

(See

Outlets for 2-Prong Plug.)

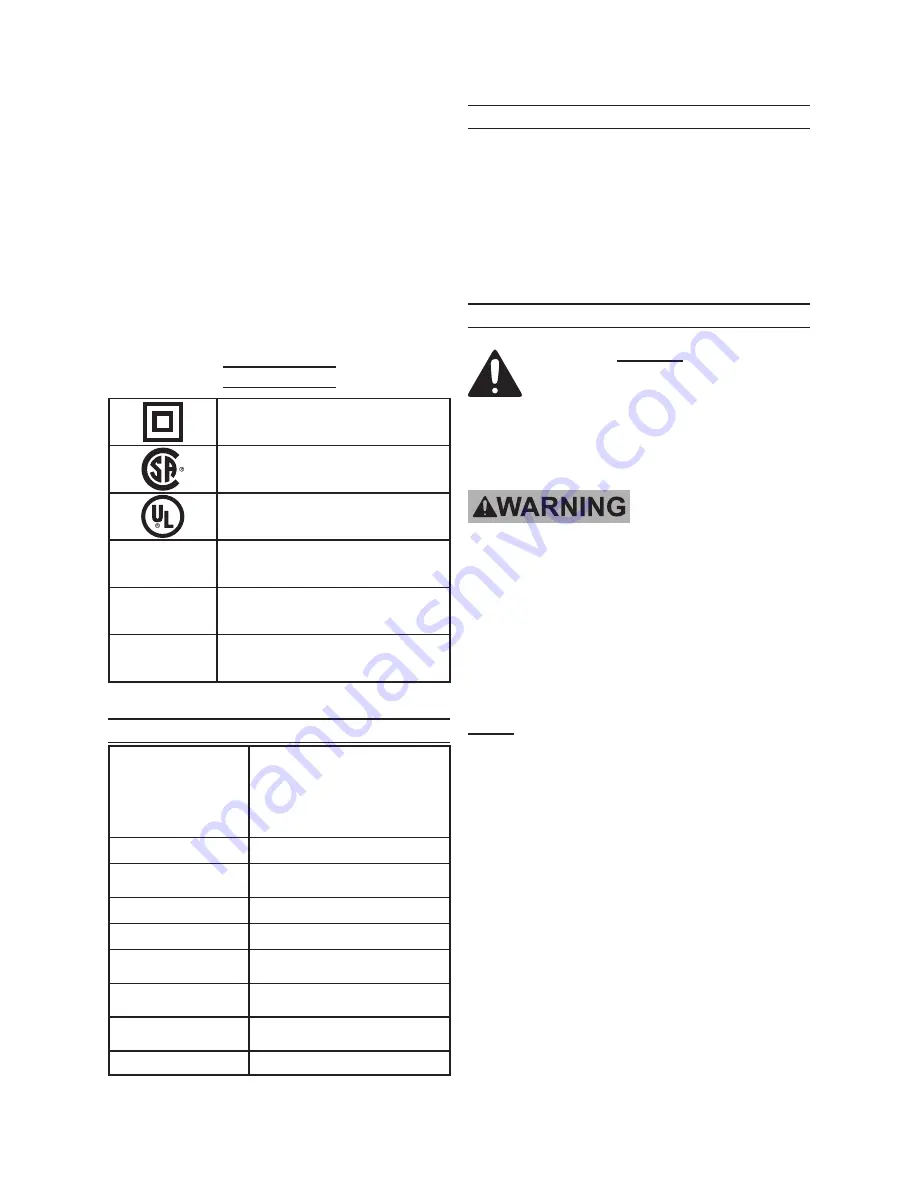

Symbology

Double Insulated

Canadian Standards Association

Underwriters Laboratories, Inc.

V~

Volts Alternating Current

A

Amperes

n0 xxxx/min.

No Load Revolutions per Minute

(RPM)

SPECIFICAtIOnS

Electrical Requirements

120 V~ / 60 Hz / 2.0 HP Motor

21.8 Start-Up Amps

9.3 No Load Amps

Motor RPM: 3400

Power Cord: 14AWGx3C

Plug: 3-Prong, Grounded

Maximum Pressure

115 PSI

Pump SCFM Maximum

6.1 CFM @ 40 PSI

3.8 CFM @ 90 PSI

Air Tank Capacity

6.34 Gallons

Tank Air Outlet Size

1/4”-18 NPT

Automatic

Start Up & Shut Off

85 PSI Start Up / 115 PSI Shut Off

Safety Valve Maximum

Pressure Rating

130 PSI

Crankcase Oil Type

SAE30 or L-DAB 100 over 50° F

SAE10 or L-DAB 68 under 50° F

Oil Capacity

8.5 ounces

unPACKInG

When unpacking, check to make sure

that the item is intact and undamaged. If

any parts are missing or broken, please

call Harbor Freight Tools at the number

shown on the cover of this manual as soon

as possible.

SEt uP InStRuCtIOnS

Read the EntIRE IMPORtAnt

SAFEtY InFORMAtIOn

section at the beginning of this

manual including all text under

subheadings therein before set

up or use of this product.

tO PREVEnt

SERIOuS InjuRY

FROM ACCIdEntAL

OPERAtIOn:

turn the Power Switch (60) of

the Compressor to its “OFF”

position and unplug the

Compressor from its electrical

outlet before set up or use of

the tool.

note:

For additional information regarding

the parts listed in the following pages,

refer to the Assembly Diagram near

the end of this manual.

IMPORTANT: Prior to first using the

1.

Compressor, the Compressor

MuSt

be filled with a high quality grade

compressor oil (not included).

Use SAE 30 or L-DAB 100 in tem

-

a.

peratures

over

50° Fahrenheit.

Use SAE 10 or L-DAB 68 in temper

-

b.

atures

under

50° Fahrenheit.

Unscrew and remove the Breather

2.

(26).

(See Figure A, next page.)

REV 08k, 09a