SKU 98917

For technical questions, please call 1-800-444-3353.

Page 13

Troubleshooting

Follow all safety precautions whenever diagnosing or servicing the

tool. Disconnect air supply before service.

Problem

Possible Solution

Air leak near top of tool.

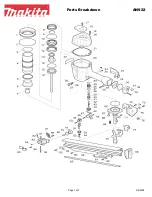

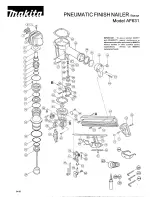

1. Tighten all screws on the cylinder cap.

(See Assy. Diagram.)

2. Have a qualified service technician install a head valve piston set.

Tool does not work.

1. Check all air connections for leaks.

2. Make sure to fully depress the nose of the workpiece when

attempting to fire a nail.

3. Check for nail jams. Clear the jam if necessary.

4. Have a qualified service technician check out the tool.

Sluggish operation.

1. Make sure the compressor regulator is set below 120 PSI. Make

sure the compressor used produces sufficient C.F.M. to operate the

Nailer.

2. Check all air connections for leaks.

3. Have a qualified service technician install a head valve piston set.

Air leak near bottom of tool. 1. Tighten all screws.

2. Have a qualified service technician replace the bumper or head

valve piston set.

Poor return after firing tool. 1. Have a qualified service technician clean the interior of the tool and/

or replace the bumper or head valve piston set.

Weak driving force.

1. Make sure the compressor regulator is set below 120 PSI.

2. Check all air connections for leaks.

3. Have a qualified service technician clean the interior of the tool

and/or replace the bumper or head valve piston set.

Poor feed.

1. Have a qualified service technician clean the interior of the tool

and/or lubricate the magazine and install a new magazine spring.

Tool jamming too often.

1. Have a qualified service technician clean the interior of the tool

and/or lubricate the magazine and install a new magazine spring.

Other problems.

1. Have a qualified service technician check out the tool.

Follow all safety precautions whenever diagnosing or servicing the

tool. Disconnect air supply before service.

Rev 09l