Page 12

SKU 95499

for technical questions, please call 1-800-444-3353.

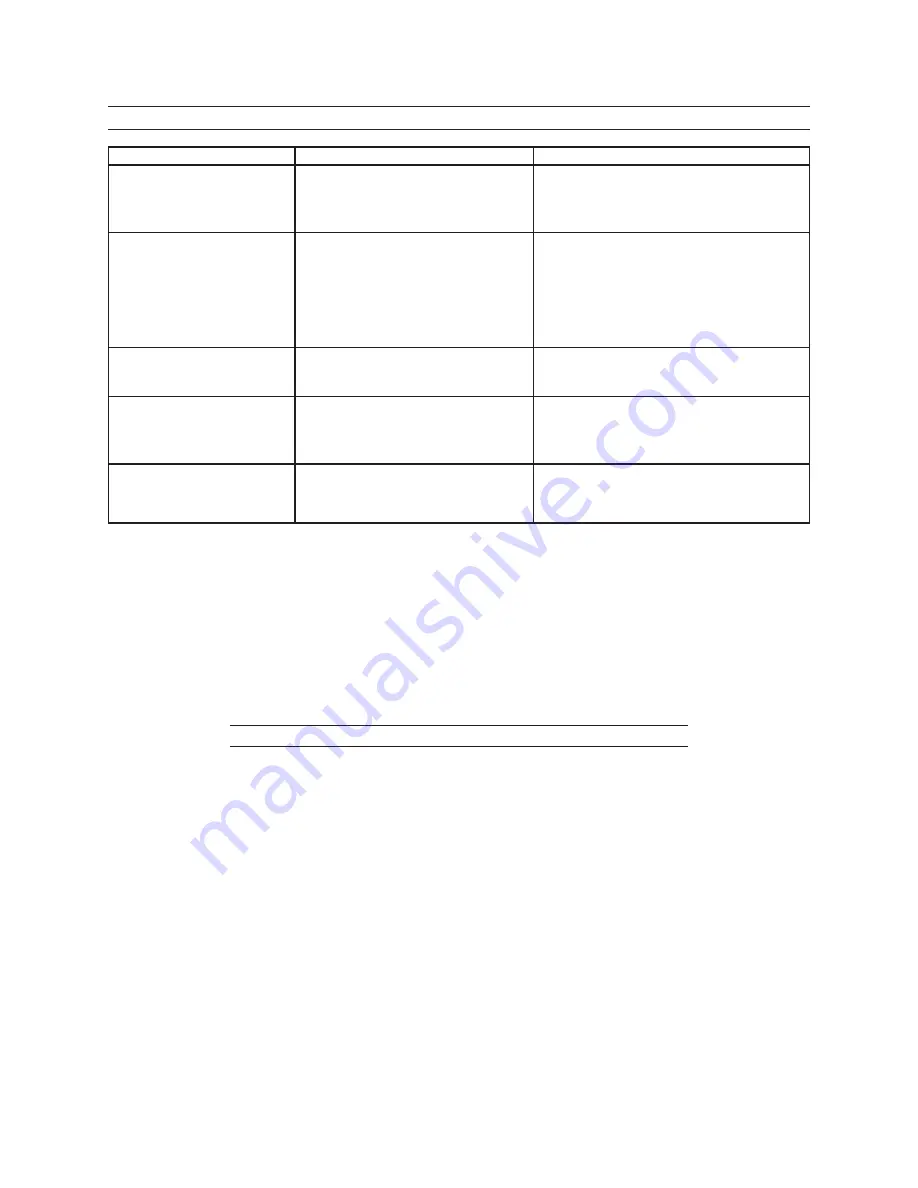

tROubLESHOOtING

Problem

Possible Cause

Possible Solution

Compressor will not start.

Blown fuse or circuit breaker tripped.

1.

Loose electrical connections.

2.

Bad Capacitors.

3.

Replace or reset fuse/circuit breaker.

1.

Make sure Compressor is plugged into a

2.

working, 120 volt, grounded, electrical outlet.

Replace capacitors.

3.

Low pressure.

Restricted air filter.

1.

Defective check valve.

2.

Air leak in safety valve.

3.

Defective Valve Plate.

4.

Replace air filter.

1.

Have a qualified service technician replace

2.

check valve.

Check valve by pulling on ring. If condition

3.

persists, have a qualified service technician

replace valve.

Replace Valve Plate.

4.

Safety valve releasing.

Defective pressure switch.

1.

Defective Safety Valve.

2.

Have a qualified service technician replace

1.

pressure switch.

Replace Safety Valve.

2.

Oil discharge in air.

Too much oil in crankcase.

1.

Compressor overheated.

2.

Restricted oil breather cap.

3.

Drain crankcase and refill to proper level on

1.

sight glass.

Reduce air pressure regulation.

2.

Clean or replace oil breather cap.

3.

Pressure switch will not turn off

Compressor.

Defective pressure switch.

Immediately unplug Compressor from its

electrical outlet. Do not operate Compressor

until a qualified service technician can replace

pressure switch.

PLEASE REAd tHE fOLLOWING CAREfuLLy

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR

DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE

OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER

AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS

SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER.

THE BUYER ASSUMES ALL RISKS AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER

INSTALLATION OF REPLACEMENT PARTS THERETO.