Page 5

SKU 95499

for technical questions, please call 1-800-444-3353.

Make sure all tools and equipment used with the Air Compressor are rated to

6.

the appropriate capacity. Do not use any tool or equipment that does not operate

from 85 PSI to 115 PSI.

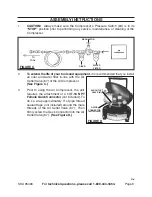

drain the Air Compressor every day.

7.

Do not allow excessive moisture to build

up inside the Air Compressor’s Tank. Do not open the Drain Valve (54) with more

than 10 PSI of air pressure in the Tank. Do not unscrew the Drain Valve so that

more than four threads are showing.

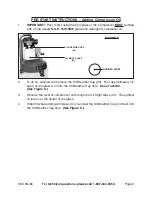

Avoid injury.

8.

Never direct the Air Outlet Valve (67) at people or animals.

do not alter or remove the Safety Release Valve (61).

9.

Make sure the Air Compressor is located on a flat, level, sturdy surface capable

10.

of supporting the weight of the Compressor, operator(s), and any additional

tools and equipment.

do not move or transport the Compressor if the Air tank (50) is under pres-

11.

sure.

Industrial applications must follow OSHA guidelines.

12.

Never stand on the Air Compressor.

13.

Serious injury could result if the Compres-

sor is tipped.

Never leave the Air Compressor unattended when it is plugged in and running.

14.

Turn off the Compressor, and unplug the unit before leaving.

do not allow children and other unauthorized people to handle or play with

15.

the Air Compressor.

do not modify the factory set pressure shutoff or startup switches.

16.

This tool will

do the work better and safer at the speed and capacity for which it was designed.

Avoid body contact with oils and lubricants used in the Compressor.

17.

If swal-

lowed, seek medical treatment immediately. For skin contact, immediately wash

with soap and water. For eye contact, immediately flush eyes with clean water.

WARNING: the brass components of this product contain lead, a chemical

18.

known to the State of California to cause birth defects (or other reproductive

harm). (California Health & Safety code § 25249.5, et seq.)

People with pacemakers should consult their physician(s) before use.

19.

Elec-

tromagnetic fields in close proximity to heart pacemaker could cause pacemaker

interference or pacemaker failure.

WARNING!

20.

The warnings and precautions discussed in this manual cannot cover

all possible conditions and situations that may occur. It must be understood by the

operator that common sense and caution are factors which cannot be built into this

product, but must be supplied by the operator.

07d